Vacuum Switches

A vacuum switch opens an electrical contact when certain fluid pressure is reached. The vacuum switch opens or closes the connections when the pressure reaches the set-point or reset-point, preventing a system from being under or overpressured.

PVL sells mechanical vacuum switches (solid state). There are three primary contact configurations for mechanical vacuum switches: normally open (NO), normally closed (NC), and changeover (Single Pole, Double Throw or SPDT).

A diaphragm or a piston opens or shuts a circuit when the pressure reaches the set-point or drops to the reset-point.

A hex key or spinning knob is often used to adjust the setting pressure of a mechanical vacuum switch. A digital display may be used to change the set-point and reset-point of an electrical vacuum switch. The disparity between the switch point and the reset point is referred to as hysteresis. The manufacturer often sets mechanical vacuum switch hysteresis, but electronic pressure vacuum hysteresis is typically adjustable.

Vacuum Switch Selection Criteria

Our vacuum switches come in a range of housing materials and seals. When choosing a material, the media and temperature range are critical factors.

When selecting a vacuum switch, consider the maximum overpressure, degree of ingress protection, ATEX approvals, resistance to vibration and shock, process connections, switch capacity, and type of electrical connection.

Vacuum Switch Applications

Popular applications for vacuum switches include:

- Air compressors

- Electric heaters

- Engine fluid systems

- Floor cleaning equipment

- Boilers

- Transmission systems

- Vacuum pumps

One of the most common industries that use vacuum pressure switches is hydraulics. Controlling pressure build-up is key for maintaining hydraulic equipment since vacuums are essential in hydraulics.

Hydraulics are often used in mechanical systems that lift, push, or pull large objects. They employ a pump that draws liquid into it, generating a vacuum at the input. When the pressure is increased, fluid is forced into the intake, causing the hydraulic equipment to move. Managing pressure and vacuum is crucial for avoiding sudden pressure fluctuations that might cause the whole hydraulic arm or lever to collapse.

Hydraulics may be found in vehicle production plants, construction machines, and amusement park rides. They're also useful for more ordinary goods like office chairs. No matter where hydraulics are used, they must operate at the appropriate pressure for the loads they are typically responsible for handling.

PVL Vacuum Switches

Pressure Vacuum Level Ltd has been selling high-quality vacuum switches for over 28 years. PVL provides these devices for various industries.

Don't hesitate to contact us if you have any questions about our vacuum switches or other products.

Other Products

PVL customers can rely on us for high-quality products. Vacuum Switches are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Pressure Switches and Transducers.

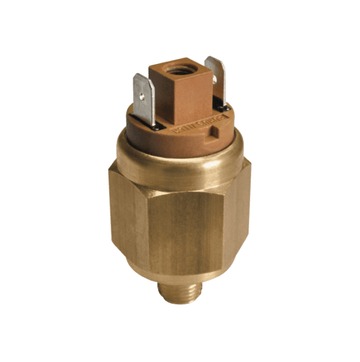

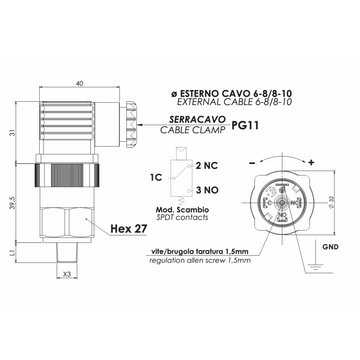

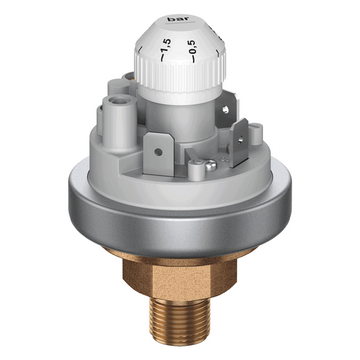

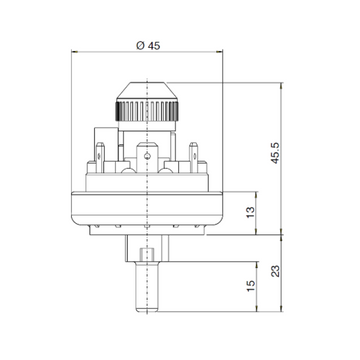

- Case Brass: (on request Stainless Steel )

- Electric contacts: Silver AgNi, on request gold plated

- Electrical connection: N.O. (White ) N.C. (Brown )

- Max switch voltage: 48V ac / dc

- Max switch current: 0,5A

- Max fluid temperature: 80°-120°C (depending on diaphragm)

- Max Overpressure limit: 15 bar

- Max Working pressure: 10 bar

- Weight ~ 70 gr

- Normal open (normal closed available)

- 1/8" BSPT (other sizes available)

|

Technical Datasheet |

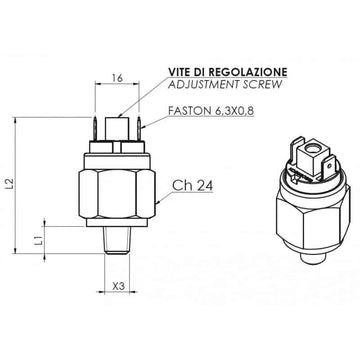

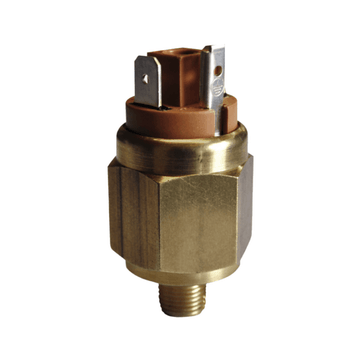

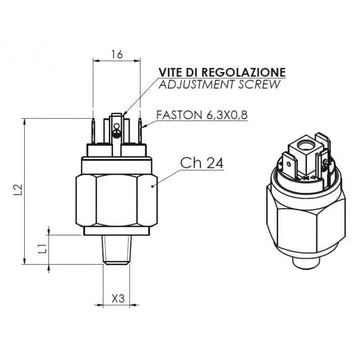

- Case Brass: (on request Stainless Steel)

- Electric contacts: Silver AgNi, on request gold plated

- Electrical connection: N.O. (White ) N.C. (Brown )

- Max switch voltage: 48V ac / dc

- Max switch current: 0,5A

- Max fluid temperature: 80°-120°C (depending on diaphragm)

- Max Overpressure limit: 35 bar

- Max Working pressure: 25 bars

- Protection degree IP00 with cover 3015010 IP54

- Weight ~ 90 gr

|

Technical Datasheet |

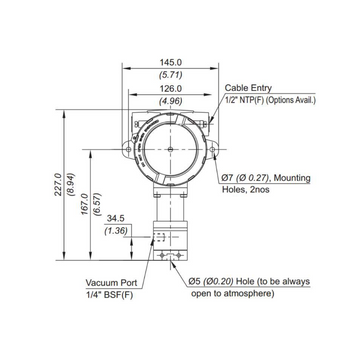

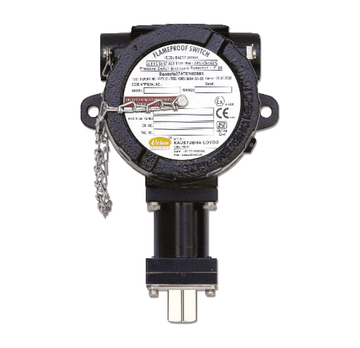

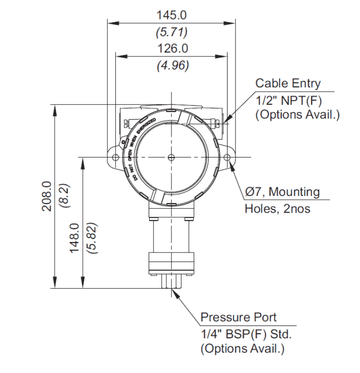

- Working pressure up to 12 bar

- SPDT or DPDT switching

- Reliable, accurate micro switches

- 1/4” BSP thread (others available)

- 316 stainless steel wetted parts

- ATEX Exd IIC T6 level of certification

|

Technical Datasheet |

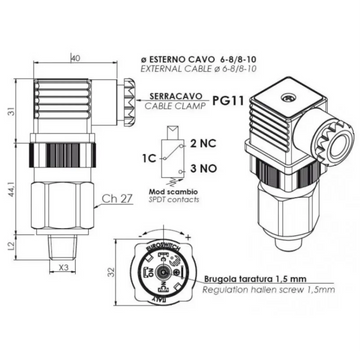

- Vacuum Switch ≤ 250V SPDT CO Contacts

- -200 / - 900 mbar adjustment ranges

- Over-pressures up to 15 bar

- Max working pressures up to 10 bar

- 1/4” BSP thread (others available)

- NBR seal or CR seal

- Brass body

|

Technical Datasheet |

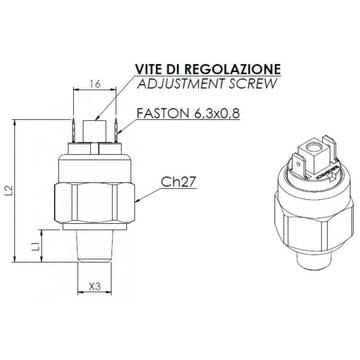

- Vacuum Switch ≤ 250V

- NO or NC Contacts

- -200 / -900 mbar adjustment range

- Over-pressures up to 35 bar

- Max working pressures up to 25 bar

- 1/4” BSP thread (others available)

- NBR seal or CR seal

- ATEX option available

|

Technical Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous or adjustable) with adjustable deadband option.

- Internal adjustment scale

- 316 stainless steel or black anodised aluminium switchcase to IP66 & IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability

|

Technical Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous or adjustable) with adjustable deadband option.

- Internal adjustment scale

- 316 stainless steel or black anodised aluminium switchcase to IP66 & IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability

|

Technical Datasheet |

- Case: Brass

- Electric Contacts: Silver

- Max Fluid Temperature: 80° to 120°c

- Max Overpressure Limit: 15 bar 15 bar

- Max Working Pressure: 10 bar 2,5 bar

- Flameproof ATEX Exd Switch with an Adjustable Change Over Contacts (SPDT) or (DPDT)

- For Adjustable Switching Pressure Ranges Up to 400 bar.

- 1/4″ BSP Female Thread (Others Available)

- Stainless Steel Diaphragm (Others Available)

- Range -1 to +3.6 Bar

- Maximum working pressures up to 12 bar

|

Technical Datasheet |

- Temperature range: Ambient temperature from –20°C to +85°C

- Diaphragm material: NBR, Silicone, FKM (Viton® ), EPDM.

|

Technical Datasheet |