Pressure Transducers

A pressure transducer is a device that measures fluid pressure and shows the force the fluid exerts on surfaces with which it comes into contact. Pressure transducers are used in many control and monitoring applications, such as flow, air speed, level, pump systems, and altitude monitoring.

To calculate pressure, the pressure transducer contains a force collector, such as a flexible diaphragm that deforms when pressurised, and a transduction element that transforms this deformation into an electrical signal. The shape and procedures of transductions are optimised to the requirements of the process under evaluation.

The most common pressure transducer designs use a force collector, a flexible diaphragm, and a transduction element that creates an electrical signal through a dependent resistive, capacitive, or inductive mechanism. The electrical device governs the components used to build the pressure sensor.

What Does a Pressure Transducer Measure?

A pressure transducer is a pressure monitoring device. It uses a sensor to convert the pressure exerted into electrical impulses. These electrical impulses are then sent to controllers or PLCs for processing and recording.

Pressure transducers employ strain gauges to detect the force applied to them. Deformation of the strain gauges results in a voltage shift. The pressure is calculated using the degree of change in voltage.

Selection Criteria

While selecting a pressure transducer, keep the following in mind:

Media type: The media utilised should be compatible with the transducer's substance.

The following are some instances of extensively used media:

- Hydraulic fluid

- Petrol/gasoline

- Adhesives

- Gases

- Water

Housing and seal material: The housing and seal material of the transducer should be chemically compatible with the application media. Stainless steel is the most often used housing material. It is more compatible with neutral and corrosive fluids and has a higher material strength. Common seal materials include nitrile butadiene rubber (NBR), Viton (FKM), and elastomers.

Temperature: High temperatures may affect transducer performance. Consequently, ensure the pressure transducer is within the application's temperature range. Pressure: The transducer must be able to withstand the operating pressure range of the application as well as overpressure. High-pressure transducers explicitly designed for extreme-pressure situations may be beneficial.

Type of transducer: Absolute and gauge pressure may be measured using capacitance and resonant wire pressure transducers. A strain gauge transducer is suited as a differential pressure transducer.

Hysteresis: A pressure transducer's capacity to provide the same result when the same rising and falling pressure is applied again. For minimum hysteresis, a capacitive pressure transducer is preferable. Repeatability: Repeatability refers to a pressure transducer's ability to provide the same output at the same pressure. It usually varies from 0.5% and 0.05%. The accuracy needed by the application will impact the transducer selection.

Approvals: Pressure transducers may need licences or certificates to operate in certain situations.

Common Applications

Pressure transducers are used to measure pressure in residential and commercial applications. Consequently, depending on the medium, there are air pressure transducers, liquid pressure transducers, and gas pressure transducers.

Typical electrical pressure transducer applications include:

- Monitoring the brake and fuel pressure in vehicles.

- Monitoring liquid levels in an HVAC system.

- Monitoring liquid and gas levels on various medical devices.

PVL Pressure Transducers

Pressure Vacuum Level Ltd has been selling high-quality pressure transducers for over 28 years. PVL provides these devices for various industries.

Don't hesitate to contact us if you have any questions about our pressure transducers or other products.

Other Products

PVL customers can rely on us for high-quality products. Pressure Transducers are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Pressure Switches and Pressure Sensors.

- Grivory, Industry First, Lightweight

- Connects to smart phones and tablets with BLE (Bluetooth® Low Energy)

- Remote Monitoring Capability Available

- Pressure ranges up to 1,000 psi 1% Standard accuracy

- Long battery life

- Alarm set points

- Secure field programmable naming

- Patent Pending Design

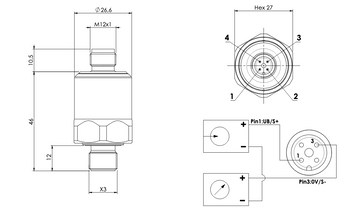

- Electronic Pressure Transducer

- 4-20mA transducer

- 0-400 bar measuring ranges

- Over-pressures up to 650 bar

- M12 electrical connector

- 1/4” BSP standard thread

- 316L stainless steel

|

ESP Technical Datasheet |

- Wireless Bluetooth Pressure Transducer

- The first Bluetooth wireless pressure transducer

- Connects to smart phones and tablets with BLE

- Pressure ranges from Vacuum to 10,000 psi

- Stainless Steel

|

Technical Datasheet |

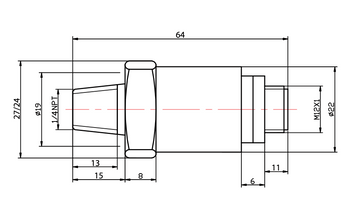

- All wetted parts 17-4 PH Stainless Steel

- Minimum IP rating of IP65 in accordance with BS EN 60529:1992.

- Frequency Response: <1ms for Conditioned Outputs

- Maximum Current Draw : 2-wire Transmitter = 20mA, Transducer in voltage mode = 4.5 mA

- EMC Data: Meets the requirements of CE.

Technical Datasheet

Technical Datasheet

- Connects to smart phones and tablets with BLE (Bluetooth® Low Energy)

- Certified Bluetooth® Wireless technology

- Pressure ranges from Vacuum to 10,000 psi

- Long battery life (proprietary technology)

- 1% Standard accuracy with optional 0.25% Ultra high accuracy

- Stainless Steel and high impact polycarbonate construction

- Alarm set points

- Secure field programmable naming

- Using BLE5 (Bluetooth® Low Energy), connect to smart phones and tablets

- Pressure ranges from Vacuum to 10,000 psi

- Long battery life

- 1% Accuracy with optional .25% ultra high accuracy

- Stainless steel wetted parts and high impact polycarbonate construction

- Alarm set points

- Secure field programmable naming

- Patent pending design

- Schrader, NPT, SAE and G ¼ pressure connection

|

Technical Datasheet |

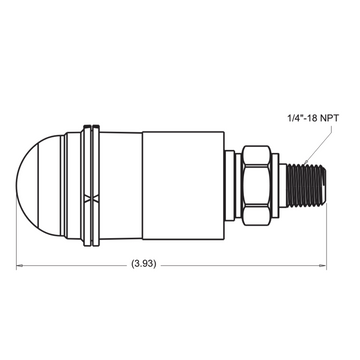

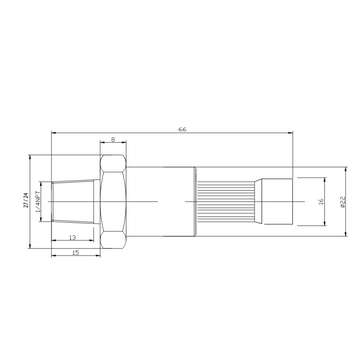

- Low Cost

- Vac Ranges to +285 psi

- Pressure Ranges 0 to 3 psi up to 10,000 psi

- Compact Design

- 316 Stainless Steel Housing

- All Stainless Steel Wetted Parts

- High 125° C (257° F) Operating Temperature

- 0.4% Accuracy

- Custom Outputs and Ranges Available

- OEM Tested & Approved

- Low Power Consumption

- Performance: @ 25°C (77 °F)

- Pressure Accuracy: 1% BFSL

- Overange Protection: 1.5x Rated

- Pressure Pressure Range: Vacuum to 1,000 psi

- All Stainless Steel Wetted Parts for Maximum Media Capability

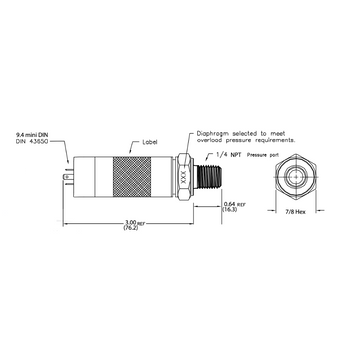

- Industrial Grade Pressure Transducer

- Overpressure protection to 3x

- Vac to 285 psi or 3 to 10,000 psi Range

- 9.4 Mini Din and Packard Electrical Connectors

- Better 0.4% Accuracy

- Custom Outputs and Ranges Available

- CE, RoHS, REACH, and Prop 65 Compliant

|

TDH43 Technical Datasheet |

- All Stainless Steel Wetted Parts for Maximum Media Compatibility

- Industrial Grade Pressure Transducer

- Overpressure protection to 3x

- Vac to 285 psi or 3 to 10,000 psi Range

- 9.4 Mini Din and Packard Electrical Connectors

- 1% Accuracy

- Custom Outputs and Ranges Available

- CE, RoHS, REACH, and Prop 65 Compliant

|

TDH33 Technical Datasheet |

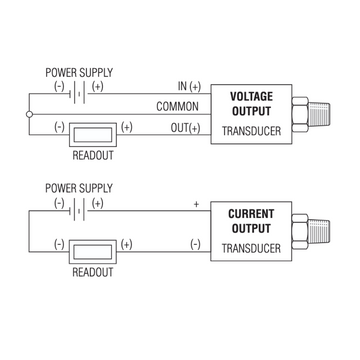

- Total Digital Design Pressure Transducer Voltage and Current outputs

- Custom pressure ranges and outputs available

- Spike Monitoring Technology

- 24V Digital Output

- Low Current Consumption

|

Technical Datasheet |