Recent Products

- Ultra-compact 316L stainless steel design (IP69, type 6P)

- No sensitivity adjustment needed for most applications

- Bright, customisable LED signal

- Immune to material buildup, flow, turbulence, and air bubbles

|

Technical Datasheet |

- Warns of overhead lightning risk even before the first lightning discharge

- Detects cloud-to-ground and as well as weaker but more common cloud-to-cloud lightning

- Detects charged precipitation

- Meets FAA performance requirements for aerodrome use

- Provides information for enhanced CAP437 reporting of thunderstorms

- Developed for marine applications both on and offshore

- Certified for marine operation for salt spray, vibration and EMC

- Meets EN50536:2011+A1:2012 requirments for a Class 1 detector

- Meets IEC 62793 performance requirements for a Class A detector

|

Technical Datasheet |

- Warns of overhead lightning risk even before the first lightning discharge

- Detects cloud-to-cloud as well as weaker but more common cloud-to-ground lightning

- Observes charged precipitation

- Meets FAA performance requirements for aerodrome use

- Meets EN50536:2011+A1:2012 requirements for a Class 1 detector

- Meets IEC 62793 performance requirements for a Class A detector

|

Technical Datasheet |

- Complete, out-of-the-box warning system with minimal installation.

- Remote access via an internet connection to view the status and warnings

- Fully automatic alarm triggering

- Warns of the most dangerous (overhead) lightning risk even before the first lightning strike

- Advanced, automatic self-test to ensure system operation

- Accurate 35km (22miles) detection range

- Professional Lightning Detector; detects cloud-to-ground, intra-cloud and cloud-to-cloud lightning

- Detects charged precipitation and strong atmospheric electric fields

- Compliance with EN50536:2011+/A1:2012 for a Class 1 detector

- Performs in accordance with IEC62793 for a Class A detector

|

Technical Datasheet |

- 10m to 99.99km measurement range (other ranges available)

- Instantaneous and averaged visibility outputs

- Transmissometer equivalent

- EXCO output (TEXCO) 39 WMO 4680 present weather codes

- Compact forward scatter design

- Hood heating for use in extreme environments

- Window heating and contamination monitoring

- Serial data output (RS232, RS422 or RS485)

- Comprehensive self-test capabilities

|

Technical Datasheet |

- 47 WMO Table 4680 present weather codes

- Reports freezing precipitation

- Designed for aviation, research and general met use

- Reliable measurement in all weather conditions

- Highly corrosion resistant hard coat anodised finish

- Window contamination monitoring and compensation

- Unaffected by obstacle warning lights

- Easy integration of Biral ALS-2 Ambient Light Sensor

- DC powered

- 10m to 99.99km measurement range

|

Technical Datasheet |

- Up to 6 Sensors wiht RS485 Interface

- Input for flow sensor

- Profinet IO Interface

- Housing for field or panel mounting

|

Technical Datasheet |

- Water protected IP67

- BNC connection and temperature input

- Life chart display

- Backlit dot matrix/clear text display and multilingual

- Data logger with files read out via USB

- Built-in foldable stand and magnet for flexible operation

- Integrated magnet at backside

|

Technical Datasheet |

- Modern and functional housing

- Excellent price-performance ratio

- Waterproof (IP65 / IP67)

- 3-line display / overhead display per button, backlight

- Robust, long battery life

- BNC connection for interchangeable electrodes

- Hold function for freezing measured values

|

Technical Datasheet |

- For conductive LF measuring cells

- Up to 4 alarm outputs

- Measurement/monitoring to USP

|

Technical Datasheet |

- 2-wire 4-20mA, 3-wire 0-10 or 0-1V

- Electrically isolated

- 4 pole measuring cell

- Scalable output

|

Technical Datasheet |

- RS485 Interface with MODBUS RTU-protocol

- 6 types of temperature compensation

- 0..20 μS/cm up to 0..500 mS/cm

- Installation with PVC-U standard fittings

|

Technical Datasheet |

- RS485 Interface with MODBUS RTU-protocol

- 6 types of temperature compensation

- 0..20 μS/cm up to 0..200 mS/cm

- Process connection G1/2" thread

|

Technical Datasheet |

- RS485 Interface with MODBUS RTU-protocol

- 6 types of temperature compensation

- 0..20 μS/cm up to 0..500 mS/cm

- Process connection G3/4" or G1A" thread

|

Technical Datasheet |

- RS485 Interface with MODBUS RTU-protocol

- Electrodes with S7/S8 or VarioPin Plug

- Integrated 1- or 2-Point

- Calibration Datalogging

|

Technical Datasheet |

- Up to 4 independent relay outputs

- Wall-mounted and panel-mounted design

- Isolated analogue current output option

- Supply voltage 230 V or 24 V AC/DC

|

Technical Datasheet |

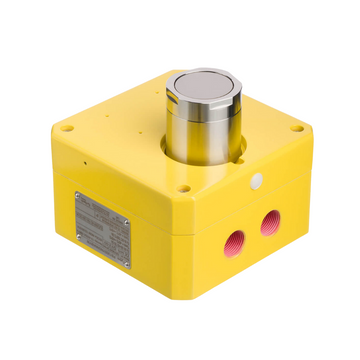

- ATEX/IECEx certified for use in explosive atmospheres

- SIL2 compliant (IEC 61508 & IEC 61511) for safety

- 316L stainless steel housing with UV-resistant paint for durability

- Compatible with PLC, ESD, and DCS systems

- Available with push button or key reset option

- IP66/67 rated for protection against dust and water

- Ideal for oil & gas, chemical, pharmaceutical, and offshore applications

|

Technical Datasheet |

- Reliable and robust for corrosive and hazardous environments

- SIL2 compliant (IEC 61508 & IEC 61511) for functional safety

- GRP housing with UV-resistant paint for durability

- ATEX/IECEx compliant and compatible with PLC, ESD, and DCS systems

|

Technical Datasheet |

- Robust and reliable for hazardous and corrosive environments

- SIL2 compliant (IEC 61508 & IEC 61511) for safety

- GRP housing with UV-resistant paint for durability

- ATEX/IECEx compliant and compatible with PLC, ESD, and DCS systems

|

Technical Datasheet |

- Robust and reliable for corrosive and hazardous environments

- SIL2 compliant (IEC 61508 & IEC 61511) for functional safety

- GRP housing with UV-resistant coating for long-lasting durability

- ATEX/IECEx compliant and compatible with PLC, ESD, and DCS systems

- Supplied with hammer and securing chain for easy operation

|

Technical Datasheet |

- Reliable and robust for hazardous and corrosive environments

- SIL2 compliant (IEC 61508 & IEC 61511) for safety

- GRP housing with UV-resistant coating for durability

- ATEX/IECEx compliant and compatible with PLC, ESD, and DCS systems

- Built-in test function for ease of maintenance

|

Technical Datasheet |

- Robust and reliable for hazardous and corrosive environments

- SIL2 compliant (IEC 61508 & IEC 61511) for safety

- 316L stainless steel housing with UV-resistant coating

- ATEX/IECEx compliant and compatible with PLC, ESD, and DCS systems

- Supplied with hammer and securing chain for ease of use

|

Technical Datasheet |

- Sounder and beacon combination for versatile signaling

- SIL2 compliant (IEC 61508 & IEC 61511) for functional safety

- Built for corrosive and hazardous environments

- 316L stainless steel housing with UV-resistant paint

- Borosilicate glass lens for durability and impact resistance

- Assembled on a 316L stainless steel backplate for strength and corrosion resistance

|

Technical Datasheet |

- Combination of sounder and beacons for effective warning signals

- SIL2 compliant (IEC 61508 & IEC 61511) for safety

- Designed for corrosive environments and hazardous areas

- 316L stainless steel housing with UV-resistant coating

- Borosilicate glass lens for durability and impact resistance

- Assembled on a 316L stainless steel backplate for strength and corrosion resistance

|

Technical Datasheet |

- Combination of sounders and beacons for effective signaling

- SIL2 compliant (IEC 61508 & IEC 61511) for safety

- Designed for hazardous and corrosive environments

- GRP housing with UV-resistant coating for durability

- Borosilicate glass 3.3 lenses for impact and thermal resistance

- 316L stainless steel backplate for enhanced corrosion resistance

|

Technical Datasheet |

- Up to 5 status lights for versatile signaling

- SIL2 compliant (IEC 61508 & IEC 61511) for functional safety

- Designed for hazardous environments and corrosive areas

- Glass-reinforced polyester (GRP) housing, UV-resistant for durability

- Borosilicate glass 3.3 lenses for high impact and thermal resistance

- 316L stainless steel backplate for corrosion resistance and strength

|

Technical Datasheet |

- Up to 5 status lights for versatile signaling

- SIL2 compliant (IEC 61508 & IEC 61511) for functional safety

- Robust and reliable for corrosive environments and hazardous areas

- GRP housing with UV-resistant paint for durability

- Borosilicate glass 3.3 lenses for high impact resistance

- Assembled on a 316L stainless steel backplate for strength and corrosion resistance

|

Technical Datasheet |

- ATEX & IECEx certified (Zones 1, 2, 21, 22)

- SIL2 compliant (IEC 61508 & IEC 61511) for functional safety

- Up to 3 selectable tones from 59 prerecorded options

- Pause function available via external switch

- Robust 316L stainless steel housing & bracket with UV-resistant coating

- High sound output up to 115 dB @ 1m

- Ingress protection: IP66/67

- Operating temp: -40°C to +70°C (T4)

- Power supply: 12–48V DC or 100–240V AC

- Custom accessories available (brackets, sunshades, labels)

|

Technical Datasheet |

- Explosion-proof sounder with up to 3 selectable tones from 59 presets

- Signal pausing via external switch

- Robust and reliable for corrosive and hazardous areas

- SIL2 compliant (IEC 61508 & IEC 61511)

- UV-resistant GRP housing with 316L stainless steel bracket

|

Technical Datasheet |

- Robust and reliable Ex beacon for corrosive and hazardous areas

- SIL2 compliant (IEC 61508 & IEC 61511)

- UV-resistant, glass-reinforced polyester (GRP) housing

- Borosilicate glass lens with optional 316L stainless steel guard

|

Technical Datasheet |

- Robust and reliable for corrosive and hazardous areas

- SIL2 compliant (IEC 61508 & IEC 61511)

- 316L stainless steel housing with UV-resistant paint

- Borosilicate glass lens with optional 316L lens guard

- Lens colors: red, amber, blue, green, yellow, or clear

|

Technical Datasheet |

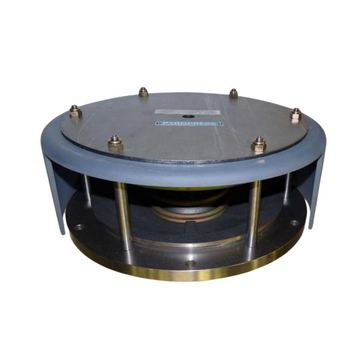

- 250mm or 300mm size option.

- Proven in service for a long life and efficiency.

- Safety deflecting cover.

- Robust and durable in the most adverse conditions.

- Custom design ability.

- Integral indicator option

- Cover: Cast aluminium

- Carrier: Cast iron

|

Technical Datasheet |

- Sizes available from 80mm to 300mm.

- Flametrap patented by BICERI.

- Proven in service for a long life and efficiency.

- Safety deflecting cover.

- Robust and durable in the most adverse conditions.

- Custom design ability.

- Options available for exhaust/high temperature applications.

- Cover: Cast aluminium.

- Carrier: Cast iron.

|

Technical Datasheet |

- Optional SIL 2 IEC 61508, with a qualifying report and Certificate Of Compliance available on request

- Epoxy painted aluminium or 316 stainless steel housing

- 316 Stainless steel wetted parts (other options available)

- 316 Stainless steel welded diaphragm

- Accuracy 0.075%

- M20 Female or 1/2″ NPT electrical connection

|

PYRP Datasheet |

|

PYRD Datasheet |

- Epoxy painted aluminium or 316 stainless steel housing

- 316 Stainless steel wetted parts. Other materials available

- Accuracy 0.075% and 0.005% available

- M20 Female

|

Technical Datasheet |

- Epoxy painted aluminium or 316 stainless steel housing

- 316 Stainless steel wetted parts. Hastelloy and others available

- Accuracy 0.075% and 0.005% available

- M20 Female

|

Technical Datasheet |

- PYRP-2000 & PYRD-2000 INDUSTRIAL SMART INDICATING PRESSURE AND DIFFERENTIAL PRESSURE TRANSMITTERS

- 316 Stainless steel wetted parts. Hastelloy and other materials available

- 316 Stainless steel welded diaphragm

- Accuracy 0.075% and 0.005% available

- M20 Female electrical connection

|

PYRP-2000 Pressure Datsheet |

|

PYRP-2000 Differential Datasheet |

- PYRP-28 INDUSTRIAL PRESSURE TRANSMITTER AND PYRD-28 INDUSTRIAL DIFFERENTIAL PRESSURE TRANSMITTER

- 316 Stainless steel wetted parts

- 316 Stainless steel welded diaphragm

- Accuracy 0.2%

- DIN 43650 plug and socket, M20 Female, flying lead or PM12 electrical connection

|

PYRP-28 Datsheet |

|

PYRD-28 Datasheet |

- PYRP-28 INTRINSICALLY SAFE PRESSURE AND DIFFERENTIAL PRESSURE TRANSMITTER

- 316 Stainless steel wetted parts

- 316 Stainless steel welded diaphragm

- Accuracy 0.2%

- DIN 43650 plug and socket, M20 Female, flying lead or PM12 electrical connection

|

PYRP-28 Datsheet |

|

PYRD-28 Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches for DPDT switching or adjustable deadband or dual independant switching

- Internal adjustment scale

- 316 Stainless steel or black anodised aluminium switchcase to IP66 and IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability.

|

Technical Datsheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches for DPDT switching or adjustable deadband or dual independant switching

- Internal adjustment scale

- 316 Stainless steel or black anodised aluminium switchcase to IP66 and IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability.

|

Technical Datsheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous operation).

- Internal adjustment scale

- Black anodised aluminium switchcase to IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability.

|

Horizontal Mounting |

|

Vertical Mounting |

|

Reed Level |

- High and low settings with pump control option

- Dual float option on reed level switch

- PPS (engineering polymer) or stainless steel case to IP66 & IP67

- DIN 43650 connector or M12 Circular connector

|

Technical Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous or adjustable) with adjustable deadband option.

- Internal adjustment scale

- 316 stainless steel or black anodised aluminium switchcase to IP66 & IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability

|

Technical Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous or adjustable) with adjustable deadband option.

- Internal adjustment scale

- 316 stainless steel or black anodised aluminium switchcase to IP66 & IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability

|

Technical Datasheet |

- 1x or 2x SPDT microswitches (simultaneous or adjustable)

- Optional adjustable deadband

- Internal adjustment scale

- 316 stainless steel or black anodised aluminium housing

- IP66 & IP67 rated

- SIL 2 certified (IEC 61508)

|

Technical Datasheet |

- Black anodised aluminium alloy housing, IP66/67 rated.

- 1 x SPDT microswitch or 2 x SPDT microswitches for simultaneous settings.

- M20 electrical entry.

- Rigid stem local mount or remote mount capillary versions.

- Sensor/thermowell lengths from 38 to 1200mm.

- Proven and documented SIL 2 IEC 61508 suitability

|

TF61 & TF62 |

|

TF615, TF625, TF616 & TF626 |

- IP66-rated housing: anodised aluminium or 316 stainless steel

- 1x or 2x SPDT microswitches (simultaneous)

- M20 entry with integral terminal block

- SIL 2 (IEC 61508) certified

- MOD approved and nuclear compliant

- Optional monitoring resistors

|

Technical Datasheet |

- IP66-rated black anodised aluminium or 316 stainless steel housing

- 1x or 2x SPDT microswitches (simultaneous operation)

- M20 entry with integral terminal block

- SIL 2 certified (IEC 61508)

- MOD approved & nuclear industry compliant

- Optional circuit monitoring resistors

|

Technical Datasheet |