Level Switches

A level switch is an electrical or mechanical method for measuring the level of a liquid, powder, or granule material. It is designed to activate an alarm if the material level in a container passes a predetermined height or depth. When a level switch detects a full tank, it is referred to as full or upper limit detection. If the level of the material drops, indicating that the tank is nearly empty, the switch will also provide an alert, referred to as empty or low level detection.

Level switches are an essential part of production operations and are used in harsh conditions with extremes in temperature, pressure, and vibrations. The diversity of level switches makes them applicable to any conditions for measuring various products. Their accuracy, reliability, and durability are a necessity for the efficiency of industrial applications.

Types of Level Switches

Level switches are used as a measurement device, a monitoring control, or a warning alarm. Level switches are equipped with a mechanical or electrical output, depending on their design, and can be open or closed.

Of the many level switches, the most commonly used are inductive, thermal, float, rotating paddle, and ultrasonic, which are used in tanks, silos, and different storage bins. Level switches are placed in control valves or pumps for fluid level control to help maintain tank levels and prevent overflow.

Level switches fall into two categories, which are point and continuous. Point level switches include optical, horizontal float, vertical, and ultrasonic. Continuous level switches include submersible, ultrasonic, and capacitive. The type of level switch used is determined by the types of measurements and the environmental conditions.

Level Switch Applications

A level switch is designed to serve a single purpose: to notify or alert controllers when a problem is detected with a product's level or presence. It signals the system when the measured level is outside the programmed parameters. Once notified, the system may activate a pump, open a valve, or take appropriate actions.

In the simplest terms, a level switch is an extra layer of protection and control to ensure efficiency and protect sensitive equipment. Read errors can occur at anytime, regardless of the system's precision. Level switches help to avoid overfills, waste, and other possible problems.

Advantages of Level Switches

Level switches are an economical method for monitoring, controlling, and regulating the levels of bulk materials and fluids or liquids. Every manufacturing process necessitates control of raw materials to avoid waste and ensure efficiency. This has become more important in today's competitive markets, where slight inconsistencies and errors can affect production and product development.

How to Choose the Right Level Switch?

There are several factors to consider when choosing the right level switch for your application. Some considerations are electrical requirements, types of wires, switch placement or positioning, type of material, and how the switch will be mounted.

PVL Vacuum Level Switches

Pressure Vacuum Level Ltd has been selling high-quality level switches for over 28 years. PVL provides these devices for various industries.

Don't hesitate to contact us if you have any questions about our level switches or other products.

Other Products

PVL customers can rely on us for high-quality products. Level Switches are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Pressure Switches and Transducers.

- Ultra-compact 316L stainless steel design (IP69, type 6P)

- No sensitivity adjustment needed for most applications

- Bright, customisable LED signal

- Immune to material buildup, flow, turbulence, and air bubbles

|

Technical Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous operation).

- Internal adjustment scale

- Black anodised aluminium switchcase to IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability.

|

Horizontal Mounting |

|

Vertical Mounting |

|

Reed Level |

- High and low settings with pump control option

- Dual float option on reed level switch

- PPS (engineering polymer) or stainless steel case to IP66 & IP67

- DIN 43650 connector or M12 Circular connector

|

Technical Datasheet |

- Maintenance-free sensor for use in many bulk materials.

- Particularly suitable for very light bulk solids

- Extension completely made of stainless steel

- Plug and play level limit switch without calibration

|

Technical Datasheet |

- Maintenance-free, very cost-effective, use in bulk materials

- Extension completely made of stainless steel

- Plug and play level limit switch without calibration

|

Technical Datasheet |

- Stainless steel – AISI 316

- SPDT reed contact

- Maximum working pressure 25 Bar

- Maximum working temperature 150 °C

- Degree of protection IP65

- ATEX Exia or Exd construction are available

Downloads

|

Technical Datasheet |

- Allowed fluid densities: 0,80 à 1,10 g/cm³

- Electric characteristics: 250 VCA /VCC 50/60 Hz

- Cut-out power: 20 (8) A

- Maximum pressure: 4 bars

- Maximum temperature: 90 °C

- Protection index: IP 68

- Housing: Copolymer polypropylene + HR HY

- Type of cable: HR HY

- Float weight without cable: 295 g

- The RFLS-53 uses the principle of high-frequency capacitive measurement.

- It responds to the mass of the material and ignores deposits and material residues on the measuring part.

- For demanding applications to indicate powder, dust and hygroscopic materials.

- The sensor is available in several versions with different types of outputs and electrical connections.

- The RFLS-53 fully replaces the older CLS-53, its electrical connection is different for the 230 VAC version (3 wires).

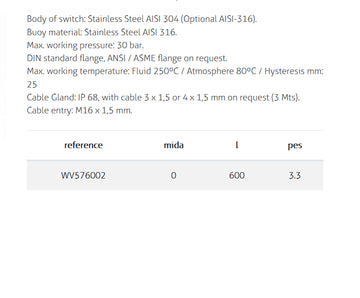

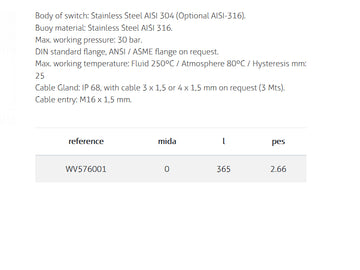

- Body of switch: Stainless Steel AISI 304 (Optional AISI-316).

- Buoy material: Stainless Steel AISI 316.

- Max. working pressure: 30 bar.

- DIN standard flange, ANSI / ASME flange on request.

- Body of switch: Stainless Steel AISI 304 (Optional AISI-316).

- Buoy material: Stainless Steel AISI 316. Max. working pressure: 30 bar.

- DIN standard flange, ANSI / ASME flange on request.

- Cable entry: M16 x 1,5 mm.

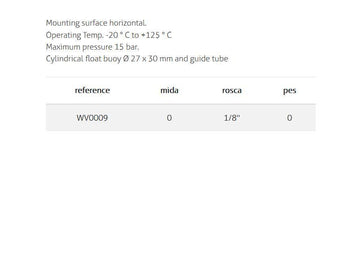

- Mounting surface horizontal.

- Operating Temp. -20 ° C to +125 ° C

- Maximum pressure 15 bar.

- Cylindrical float buoy Ø 27 x 30 mm and guide tube

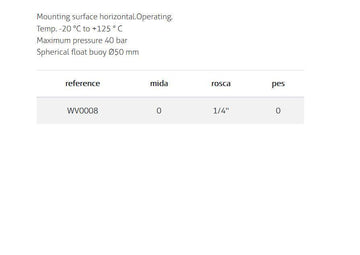

- Mounting surface horizontal.Operating.

- Temp. -20 °C to +125 ° C

- Maximum pressure 40 bar

- Spherical float buoy Ø50 mm

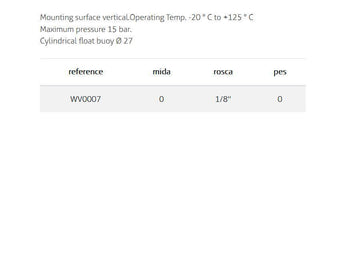

- Mounting surface vertical. Operating Temp. -20 ° C to +125 ° C

- Maximum pressure 15 bar.

- Cylindrical float buoy Ø 27

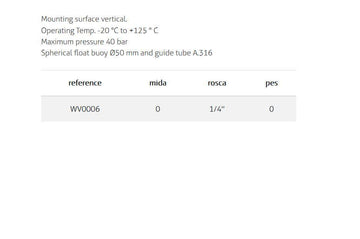

- Mounting surface vertical.

- Operating Temp. -20 °C to +125 ° C

- Maximum pressure 40 bar

- Spherical float buoy Ø50 mm and guide tube A.316

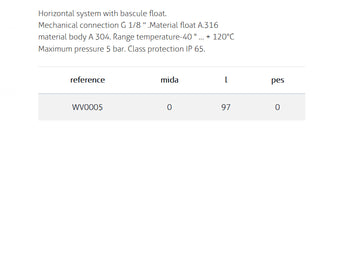

- Horizontal system with bascule float.

- Mechanical connection G 1/8"

- Material float A.316 material body A 304. Range temperature-40 ° + 120°C

- Maximum pressure 5 bar. Class protection IP 65.

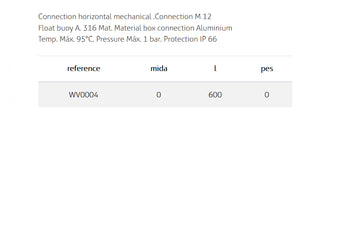

- Connection horizontal mechanical .Connection M 12

- Float buoy A. 316 Mat. Material box connection Aluminium

- Temp. Máx. 95°C. Pressure Máx. 1 bar. Protection IP 6

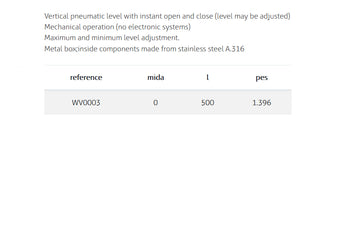

- Vertical pneumatic level with instant open and close (level may be adjusted)

- Mechanical operation (no electronic systems)

- Maximum and minimum level adjustment.

- Metal box inside components made from stainless steel A.316

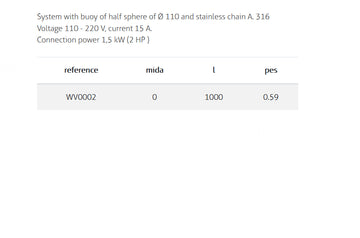

- System with buoy of half sphere of Ø 110 and stainless chain A. 316

- Voltage 110 - 220 V, current 15 A.

- Connection power 1,5 kW (2 HP )

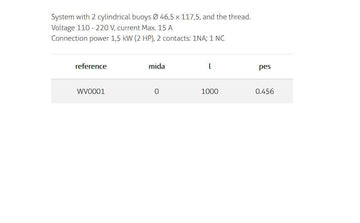

- System with 2 cylindrical buoys Ø 46,5 x 117,5, and the thread.

- Voltage 110 - 220 V, current Max. 15 A

- Connection power 1,5 kW (2 HP), 2 contacts: 1NA; 1 NC