Continuous Oil-Separator Monitoring System (COMS)

- Equipment Type: Alarm system for oil separators

- Liquid: Diesel / Heating Oil, Petrol, Oil

- Vessel: Oil Separator

- Temperature: -40.00 °C up to 85.00 °C

- Certification: ATEX, IECEx

- Power Supply: 230 VAC

- Additional criteria: Has display

- Description

- Features

- Benefits

- Product Catalogue

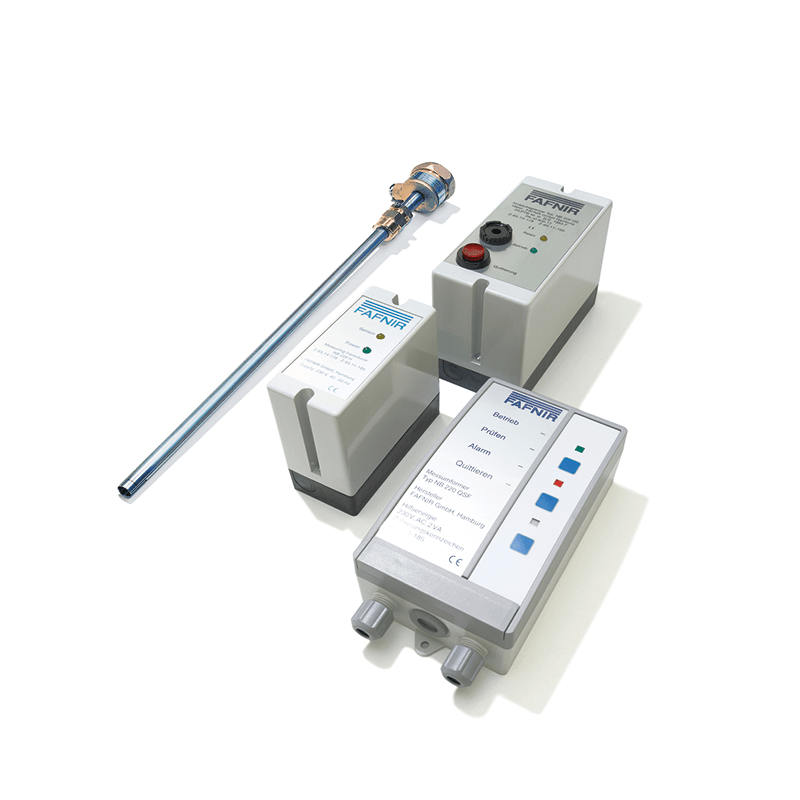

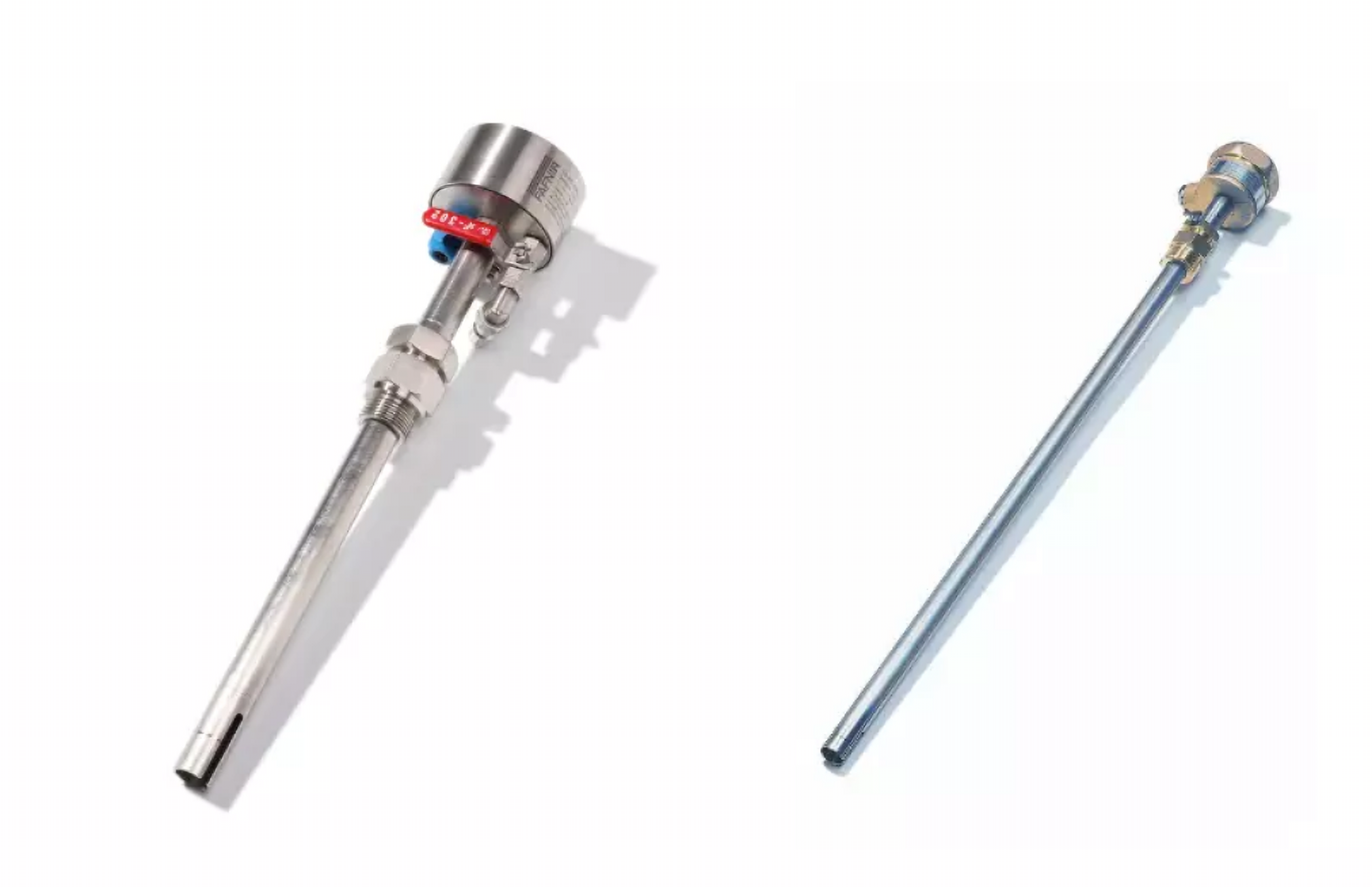

The first of its kind solution for the continual monitoring of oil separators for the thickness of the oil layer and the content of sludge. The complete COMS solution from FAFNIR comprises the new sophisticated ultra-sonic sludge sensor, suspended in the oil separator, continually taking readings to measure the height and temperature of sludge in the reservoir.

Alongside the ultra-sonic sensor is the VISY-Stick with a special separation float monitoring the thickness of the oil level. These two readings combined give the complete picture of the contents of the oil separator, something which has, until now, only been achievable manually. The readings will be visualized by the VISY-Command GUI/Web and permanently stored in the operations diary. The VISY-Command Web can additionally be relayed to the SECON-X server for remote server based access anytime, anywhere.

- Continuously monitors the thickness of the oil

- Continuously monitors sludge layer thickness in the reservoir

- Self-monitoring

- Alarms with email alerts

- Detailed real-time data for reporting and analysis

- High quality stainless steel construction

- Easy to retrofit with an existing VISY-X ATG-System

- Integrated oil separator alarm indicator (oil layer thickness / overfill)

- Integrated operations diary

No risk to your employees and no loss of sales

- Eliminates/reduces the risk of accidents caused during oil-separator monitoring/inspection (HSSE)

- Eliminates/reduces the necessity to block off areas, preventing waiting times and losses of sales.

Become pro-active rather than reactive

- Oil Separators are emptied regularly without knowing if it is required. With this new solution, it is only done when necessary.

- Trend data analysis can give a clear insight into when the next clean will be necessary, alleviating unplanned expenses which occur suddenly.

Only pay for what is removed

- Instead of emptying a full reservoir, you only pay for what is removed (e.g. water/water and oil/water, oil and sludge.)

Reduce environmental risks

- Alarms for overflow reduce the risk of pollution and related fines.

Continuous visibility

- Whether installed as a VISY/SECON system or integrated with DOMS PSS 5000 the COMS solution offers users the ability to access data from a centralised location or even via mobile, making the regular reports easy to access.

Data

- All measuring data will be stored in a database and can be used for analyses and reports.

Robust hard-wearing design

- Only the highest quality stainless steel is used for construction.

Customers also viewed

£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid£0.00

Liquid error (snippets/product-item line 160): Could not find asset snippets/rfq_button.liquid