Float & Level Switches

Monitoring and control of liquid, powder, or granulated material levels and residual volume are required in factories, plants, various equipment, rivers, and utility water tanks. Level switches and level metres detect and measure commodities such as liquids, powders, and granular particles in tanks, containers, and pipes.

The switch detects the electrical difference between empty and full containers of material to determine the amount. When the material is empty, the detecting and grounding electrodes' electrical states are as follows: resistance (Ro) is infinite, and capacitance (Co) is a specific capacitance value specified by the installation status.

A level switch is a kind of sensor that detects liquids, powders, or grains in a specific location, and it is sometimes referred to as a level sensor.

When a tank is full of fluid, for example, it will overflow, a level switch is installed at the tank's top to prevent overflow. When the liquid makes contact with the level switch, a signal is sent to prevent the liquid from overflowing the tank. (The identification of the presence of a substance in a tank is known as full detection or upper limit detection.)

On the other hand, a level switch is used to keep the tank from being completely emptied when the liquid level falls as it is released. This is referred to as a lower limit or empty detection.

Manufacturing facilities are using a wide variety of sensors as they put a greater emphasis on energy saving. Level sensors are used in challenging environments with high temperatures, pressures, vibration, and surroundings.

Level sensors detect a wide range of objects. Under these conditions, level sensors must be very reliable. Our level sensors meet these requirements. They are created with a high level of skill and technological knowledge.

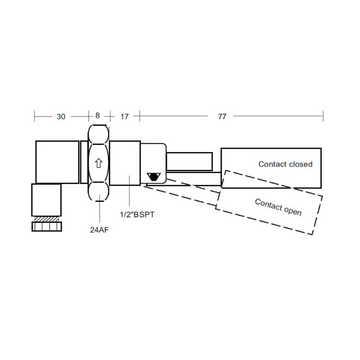

- All 304 grade stainless steel construction

- Strong hinge pin and up to 5 bar pressure

- 1/2” BSPT external fitting level switch

- 300Vac/50VA

|

Technical Datasheet |

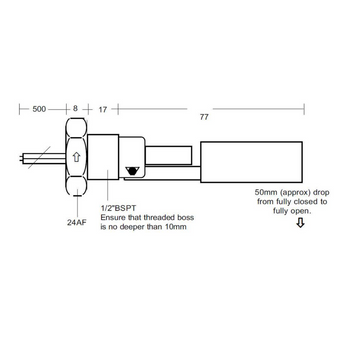

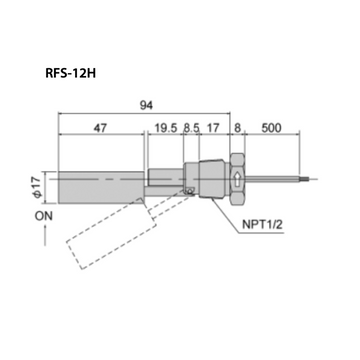

- All 304 grade stainless steel construction

- Strong hinge pin and up to 5 bar pressure

- 1/2″ BSPT external fitting level switch

- 300Vac/50VA

- 500mm Flying Leads

|

Technical Datasheet |

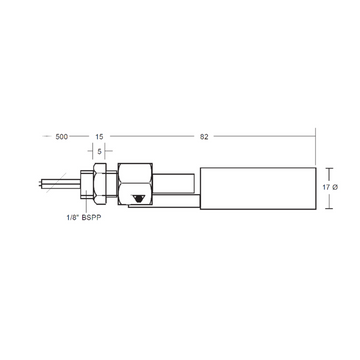

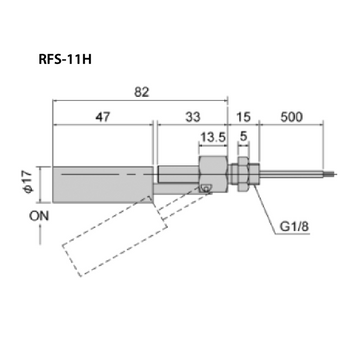

- 304 grade stainless steel construction

- Strong hinge pin and up to 5 bar pressure

- 1/8” BSP internal fitting option

- N/O or N/C (reversible) contact

- 300Vac/50VA

|

Technical Datasheet |

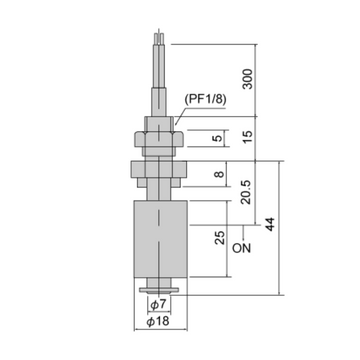

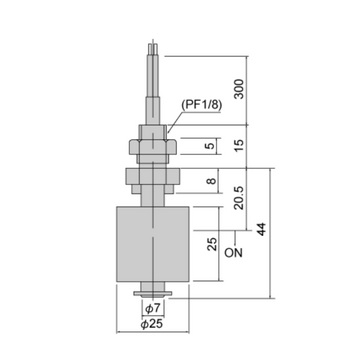

- Polypropylene foamed float 18 Ø

- Max Pressure 3 bar

- Polyprop. top entry stem level switch

- N/O or N/C (reversible) contact

- 1/8” BSP thread with nut

- 300Vac/66VA

|

Technical Datasheet |

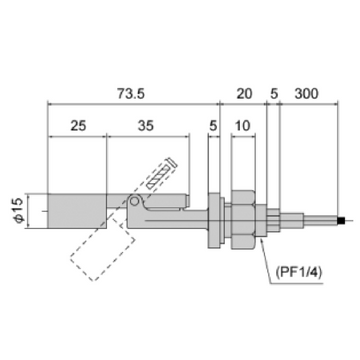

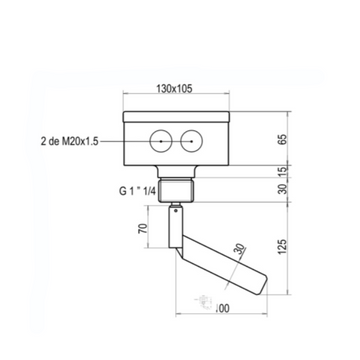

- Polypropylene float & body

- Max Pressure 3 bar

- Polyacetal side entry stem level switch

- N/O or N/C (reversible) contact

- 1/4” BSP thread with nut 300Vac/66VA

- Max Temperature 80 °C

|

Technical Datasheet |

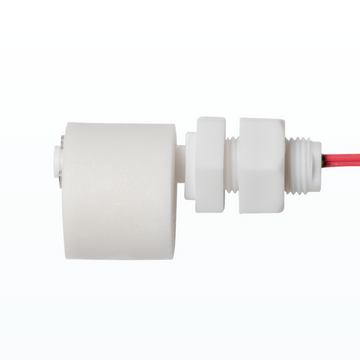

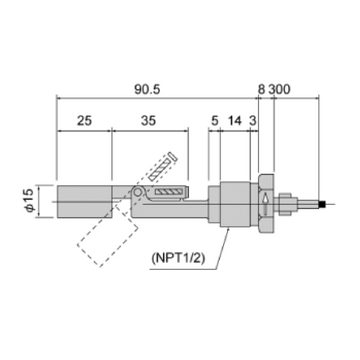

- Polypropylene Body & Float (N1)

- Nylon Body & Float (N2)

- External side entry fitting level switch

- 1/2” BSPT (NPT tapered) thread

- N/O or N/C (reversible) contact

- 300Vac/50VA reed switch

- Max Temperature 110 °C

|

Technical Datasheet |

- All 316 grade stainless steel

- Pressures up to 40 bar

- 120°C maximum temperature

- N/O or N/C (reversible) contact

- 1/8” BSP thread with nut

- 300Vac/50VA

|

Technical Datasheet |

- Nitrile foamed float 26mm Ø

- Max Pressure 15 bar

- Polyacetal top entry stem level switch

- N/O or N/C contacts (reversible float)

- 1/8” BSP thread with nut

- 300Vac/66VA

|

Technical Datasheet |

- Nitrile float

- Max Pressure 15 bar

- Polyacetal side entry stem level switch

- N/O or N/C (reversible) contact

- 1/4” BSP thread with nut

- 220Vac/66VA

|

Technical Datasheet |

- All 316 grade stainless steel

- Side entry applications

- 120ºC maximum temperature

- N/O or N/C (reversible) contact

- 1/8” BSP thread with nut

- 300Vac/50VA

|

Technical Datasheet |

- 316 grade stainless steel level switch

- Pressures up to 10 bar

- 120ºC maximum temperature

- N/O or N/C (reversible) contact

- 1/8” BSP thread with nut

- 300Vac/50VA

|

Technical Datasheet |

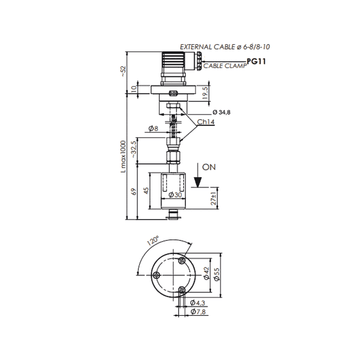

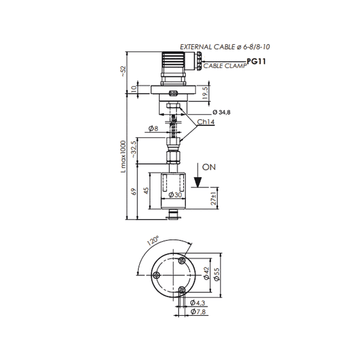

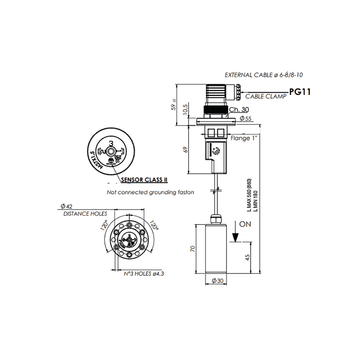

- Nylon or NBR Float

- Adjustable length to 1000 mm

- NO/NC or SPDT Reed Switch

- Temperature Switch Option (PKT)

- IP65 with Din Connector Flange or 1” BSP Options

|

Technical Datasheet |

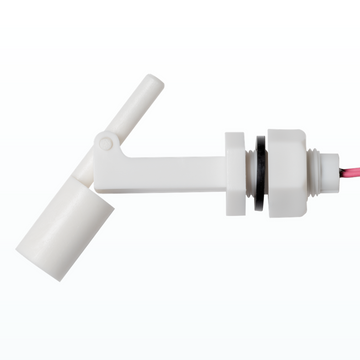

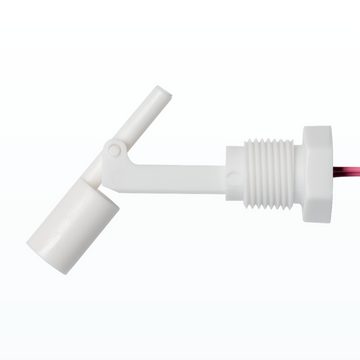

- Polypropylene float & body material

- Internal side entry entry fitting

- 1/4″ BSP thread with nut

- N/O or N/C (reversible) contact

- 300 Vac/50VA reed switch

- Low cost Level Switch for OEM applications

|

Technical Datasheet |

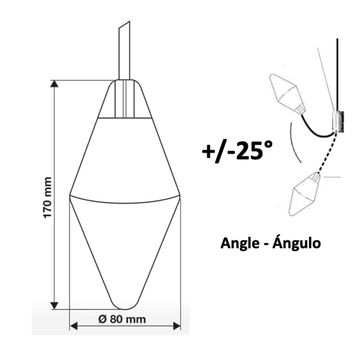

- Omni Directional Operation

- Switching angle+/- 25º

- Maximum pressure 3.5 bar

- Allowed Fluid Density 0.70 to 1.15

- 16A resistive - 6A inductive

- 6m, 13m, 15m, 20m, 25m Sizes Available On Request

|

Technical Datasheet |

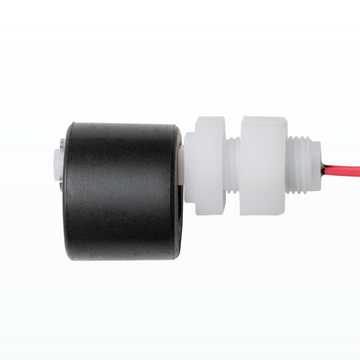

- Polypropylene float & body material

- External side entry entry fitting level switch

- 1/2″ BSPT (NPT tapered) thread

- N/O or N/C (reversible) contact

- 300 Vac/50VA reed switch

- Low cost Level Switch for OEM applications

|

Technical Datasheet |

- Nylon or NBR Float

- Adjustable length to 1000 mm

- NO/NC or SPDT Reed Switch

- Temperature Switch Option (PKT)

- IP65 with Din Connector Flange or 1” BSP Options

|

Technical Datasheet |

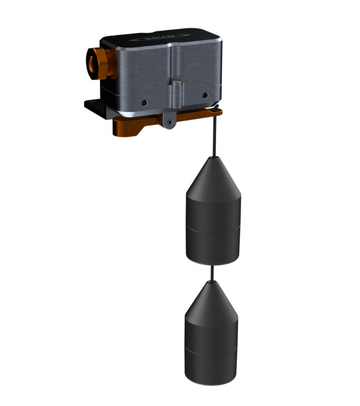

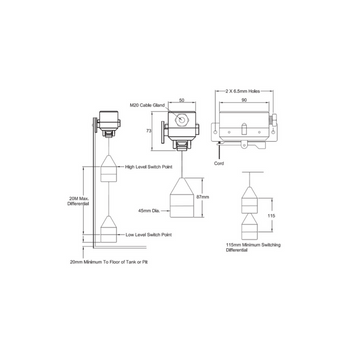

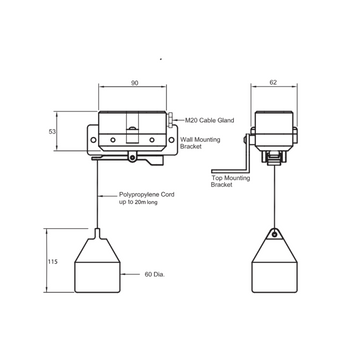

- Australian Made

- High and Low Level Control

- 2 HP 1.5kW 20 AMP 500V S.P.D.T switch

- No metal parts in contact with liquids

- Heavy duty all metal housing

- Weatherproof to IP67

- Super reliable magnetic action

|

Technical Datasheet |

- 180ºC High Temperature Version

- 304 grade stainless steel construction

- Hinge pin and up to 5 bar pressure

- 1/8” BSP internal fitting or 1/2” external fitting options

- N/O or N/C (reversible) contact

- 300Vac/50VA

|

Technical Datasheet |

- Industrial Grade Pressure Transducer

- 1.5x Over Pressure

- 4-20mA Output

- Various Cable Lengths

- 0.5% Accuracy

- Nose cone or 1/4 NPT

- Optional Suggested Desiccant Filter

|

Technical Datasheet |

- High temperatures up to 200°C

- Pressures up to 10 bar

- All 316 grade stainless steel

- N/O or N/C (reversible) contact

- 3/8” BSP thread with nut

- 300Vac/50VA

|

Technical Datasheet |

- Unsinkable Polypropylene float

- Max Pressure 3 bar

- Polypropylene stem with 30cm leads

- N/O & N/C contacts (reversible float)

- Level switch has M8 thread with nut

- 220Vac/66VA

|

Technical Datasheet |

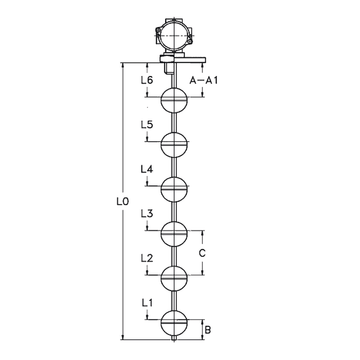

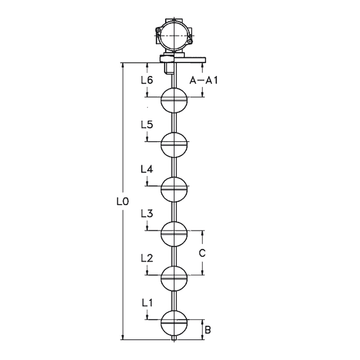

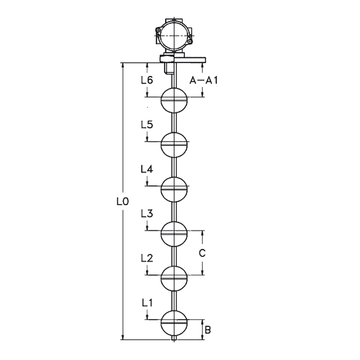

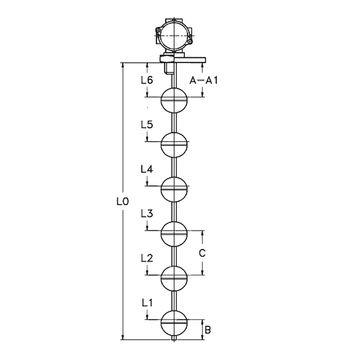

- 1 to 6 switch points

- Up to 5m length.

- Up to 6 bar max working pressure

- Working temperature Up to 130°C

- IP65 Rated

- ATEX Options Available

|

Technical Datasheet |

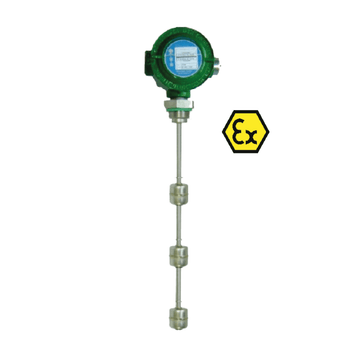

- 1 to 6 switch points Up to 5m length.

- Up to 6 bar max working pressure

- Working temperature

- Up to 130°C IP65

- Rated Choice of Threads

- Terminal head, Flying Leads, DIN connector Options.

- Various Floats Available ATEX Exd

|

Technical Datasheet |

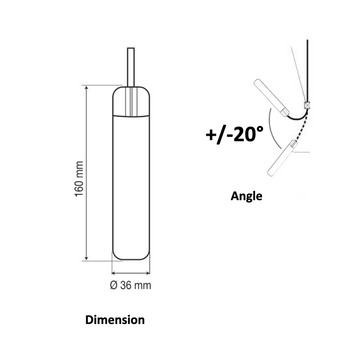

- Omni Directional Operation

- Switching angle+/- 20º

- Maximum pressure 5.5 bar

- Allowed Fluid Density 0.70 to 1.15

- 12A resistive - 6A inductive

- 2, 3, 5, 10 and 20m Options

|

Technical Datasheet |

- Important specification: Only in non ATEX area

- Electric characteristics: 250 VCA 50/60 Hz

- Cut-out power: 4 A

- Maximum temperature: -20 - + 60°C

- Protection index: IP 40 - 53

- Membrane: Nitrilo

- Body: Glass fiber reinforced plastic

- Float weight without cable: 480 g

|

Technical Datasheet |

|

Wiring Diagram |

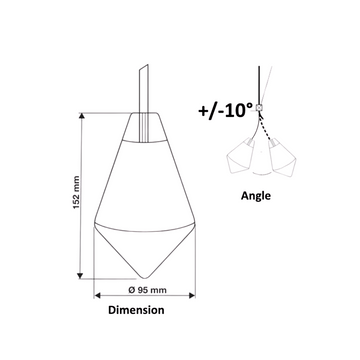

- Tilting Operation

- Switching angle+/- 10º

- Temperature -40º to 85ºC

- Bulk Solids High Level Measurement

- 20A resistive - 8A inductive

- 5, 6, 13, 15, 20 and 30m Options

|

Technical Datasheet |

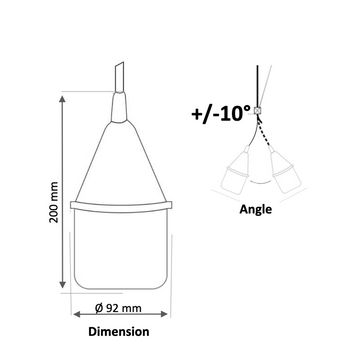

- Tilting Operation

- Switching angle+/- 10º

- Temperature -20º to 70ºC

- Bulk Solids High Level Measurement

- 10A resistive - 4A inductive

- 5, 10, 15, 20, 25 and 30m Options

|

Technical Datasheet |

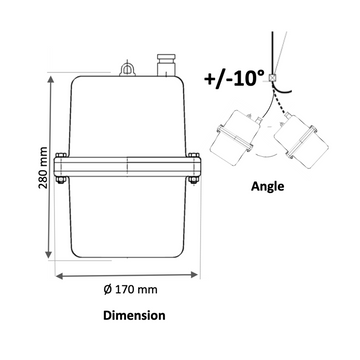

- Tilting Operation

- Switching angle+/- 10º

- Temperature -20º to 70ºC

- Bulk Solids High Level Measurement

- 10A resistive - 4A inductive

- 5, 10, 15, 20, 25 and 30m Options

|

Technical Datasheet |

|

Technical Datasheet |

- High and low settings with pump control option

- Dual float option on reed level switch

- PPS (engineering polymer) or stainless steel case to IP66 & IP67

- DIN 43650 connector or M12 Circular connector

|

Technical Datasheet |

- 1 x SPDT microswitch or 2 x SPDT microswitches (simultaneous operation).

- Internal adjustment scale

- Black anodised aluminium switchcase to IP67 standards

- Proven and documented SIL 2 IEC 61508 suitability.

|

Horizontal Mounting |

|

Vertical Mounting |

|

Reed Level |

- Heat resistant up to 200℃

- Vertical threaded mounting

- SUS316 stainless steel body

- Float SG: 0.55±0.05 (light liquids)

- 50W, 300V, 0.5A DC/AC rating

|

Technical Datasheet |

- Operation mode: By tilting

- Electric characteristics: 240 VCA 50/60 Hz

- Cut-out power: See SOLIBA or SOLIBA EX P

- Maximum temperature: See SOLIBA or SOLIBA EX P

- Protection index: IP 68

- Housing: Cast aluminium

- Type of cable: Neoprene ou HR HY 3X1 mm²

|

Technical Datasheet |

- Nitrile foamed float 20mm Ø

- Max Pressure 15 bar

- Polyacetal top entry stem level switch

- Close on fall contact

- 1/8” BSP thread with nut

- 220Vac/66VA

|

Technical Datasheet |

- Unsinkable Polypropylene float

- Max Pressure 3 bar

- Polypropylene stem with 30cm leads

- Make on rise contact (not reversible)

- M10 thread with nut

- 220Vac/66VA

|

Technical Datasheet |

- Polypropylene foamed float 25mm Ø

- Max Pressure 3 bar

- Polyprop. top entry stem level switch

- N/O or N/C (reversible) contact

- 1/8” BSP thread with nut

- 300Vac/66VA

|

Technical Datasheet |

- Polypropylene body & float (N1)

- Nylon body & float (N2)

- Internal side entry fitting

- 1/4” BSP thread with nut

- N/O or N/C (reversible) contact

- 300Vac/50VA reed switch

- Max Temperature 110 °C

|

Technical Datasheet |

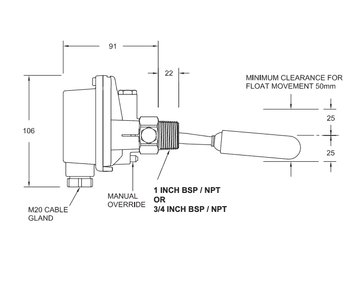

- Stainless steel or thermoplastic

- Built in manual override

- 15 Amp 500 volt S.P.D.T switch

- Unique seal-less coupling

- Weatherproof IP67 housing

- Simple to install

- Fully serviceable

- 1 to 6 switch points

- Up to 6m length.

- Up to 50 bar max working pressure

- Working temperature Up to 105°C

- IP65 Rated

- ATEX Options Available

- 1 to 6 switch points

- Up to 6m length.

- Up to 20 bar max working pressure

- Working temperature Up to 105°C

- IP65 Rated

- ATEX Options Available

|

Technical Datasheet |

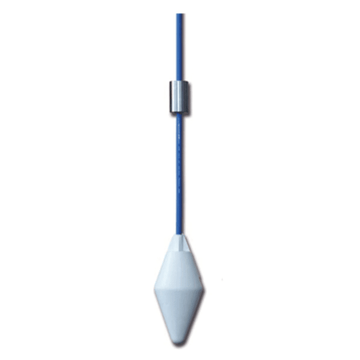

- Use Mineral oils: Fuels

- Type of contact: Reed SPST/SPDT

- Max switch. capacity: 80 W (50W SPDT)

- Max switch. current: 1 A

- Max switch. voltage: 250 Vac (220 Vac SPDT)

- Fluid specific weight: > 0,85 with L max

- Working temperature: -15°C/+100°C

- Weight ~ gr 145

- Clear, clean liquids, rain water

- Wastewater, sewage water, charged liquids

- Slightly aggressive liquids (oils, mud, paint, etc.) and more aggressive liquids if equipped with a HR HY cable

- Level control of multiple pumps

- Overflow or dry-running protection

- High / low level alarm

- Aggressive liquids : acids, solvents, corrosive liquids, hydrocarbons, sea water, etc.

- Level control of multiple pumps

- Emptying / Filling function

- Overflow or dry-running protection

- High / low level alarm

- Allowed fluid densities: 0,70 à 1,15 g/cm³

- Electric characteristics: 12,24,48 VCA /VCC - 250 VCA - 50/60 Hz

- Cut-out power: 16 (6) A Maximum pressure: 3,5 bars

- Maximum temperature: 85 °C

- Protection index: IP 68

- Omni Directional Operation

- Switching angle+/- 25º

- Maximum pressure 4 bar

- Allowed Fluid Density 0.70 to 1.15

- 16A resistive - 6A inductive

- 5, 10, 13, 15, 20, 25 and 30m Options

|

Technical Datasheet |

- Omni Directional Operation

- Switching angle+/- 110º

- Maximum pressure 3.5 bar

- Allowed Fluid Density 0.70 to 1.15

- 20A resistive - 8A inductive

- 1, 3, 5, 10 and 20m Options

- 5 to 500V AC 15A 1.5kW (2HP)

- Switch Gold Contact Low Wetting Current model available No metal parts in contact with liquids

- 60mm level change on to off or off to on

- Highly reliable magnetic action

- Fully sealed IP67 electrical housing

- M20 cable gland built in

- Operation mode: by rotation

- Important specification: ATEX Only in non ATEX area

- Measuring blade speed: 5 rpm

- Electric characteristics: 230 VCA 50/60 Hz Option :24VCA/VDC

- Cut-out power: 2A

- Maximum temperature: -20 - + 60°C

- Protection index: IP 65 - 53

- Vanes: Inoxidable AISI 304 o 316

- Body: Glass fiber reinforced ABS

- Float weight without cable: 800 g

|

Technical Datasheet |

- Operation mode: By tilting

- Important specification: Allows for the detection for very light products

- Housing material: Stainless steel food 18/10

- Tilt weight without device: 300 g

|

Technical Datasheet |

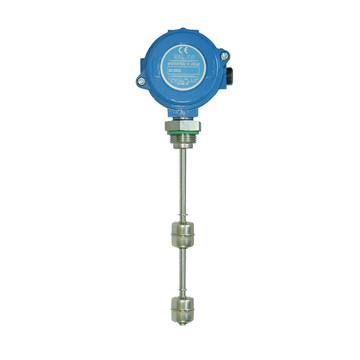

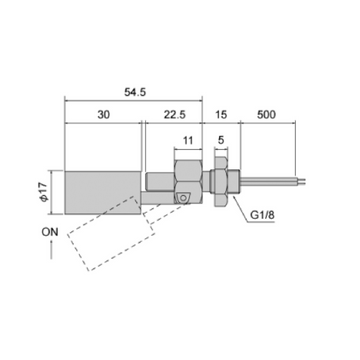

- Compact, durable SUS304 stainless steel design

- Operates from -40℃ to +120℃, 0.5 MPa pressure

- For water, oil, and chemical detection

- Side-threaded for easy installation

- Ideal for UV devices, boilers, and marine systems

|

Technical Datasheet |

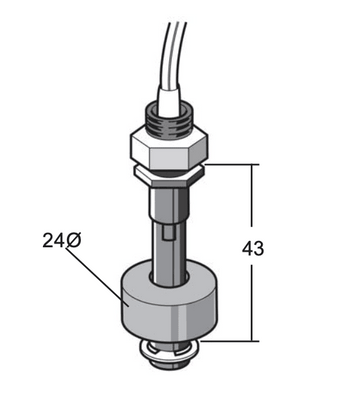

- Only 55mm protrusion into tank

- Standard 1/8” BSP thread 15mm long

- 304 grade stainless steel construction

- Float SG = 0.80 +/-0.05

- Up to 120 C temperature & 5 bar

- 24Vdc/0.1A max

|

Technical Datasheet |