HONSBERG

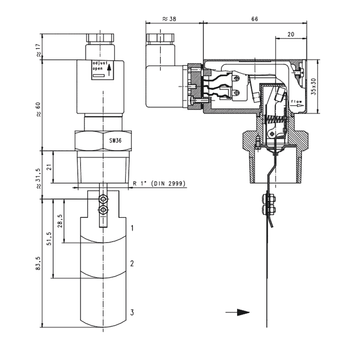

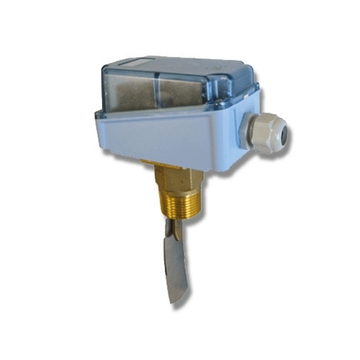

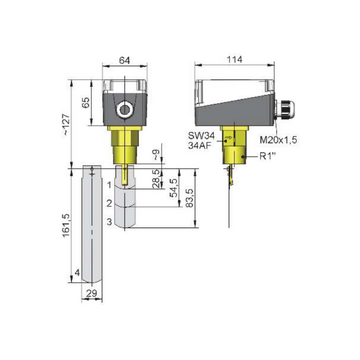

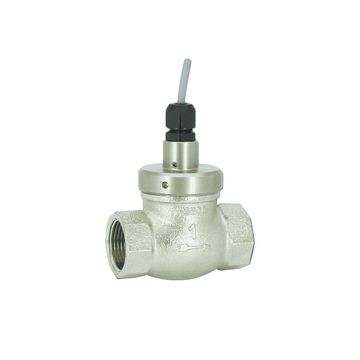

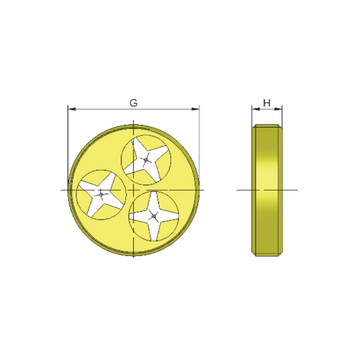

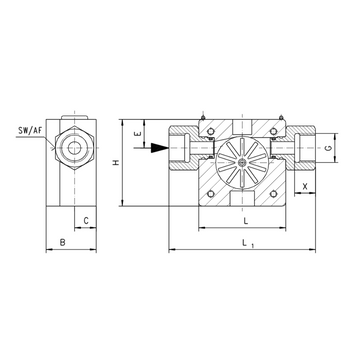

- 4 x paddles supplied with each switch

- Pipe sizes from 25mm to 200mm

- 1”BSP threaded pipe fitting

- Brass or stainless steel option

- 0.9 - 6.7 m3/h H2O switching range

- C/O Micro-switch Rated 250Vac/5A

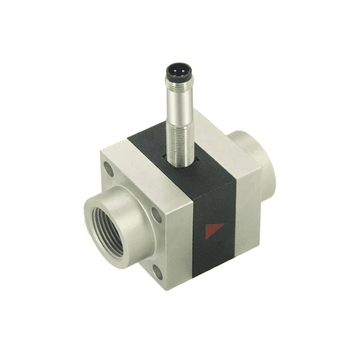

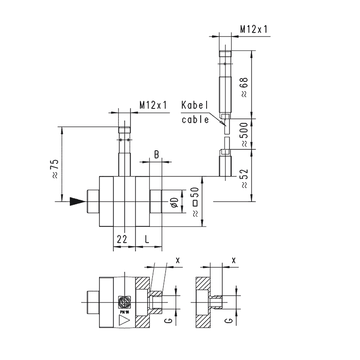

- Works with 2- and 3-wire GHM sensors

- USB plug-and-play connection

- On-site setup and updates

- Auto sensor detection

- Full accessory kit included

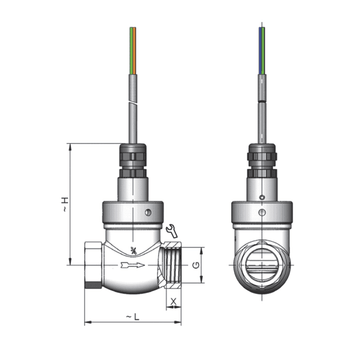

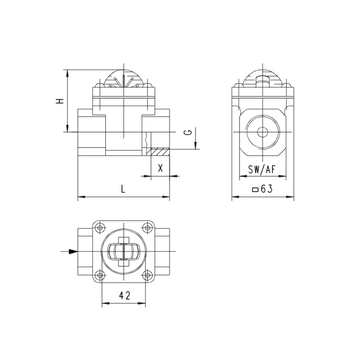

- 4 x paddles supplied with each switch

- Pipe sizes from 1” to 6” diameter.

- Standard 1” BSP fitting

- 0.19 to 39.90 m³/h switching ranges

- Brass or stainless steel body

- C/O Micro-switch Rated 250Vac/15A

- Parameterisation of LABO/FLEX/OMNI

- For Windows PC with USB

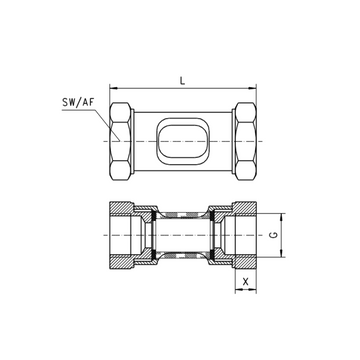

- Connection in device supply line

- Bypass mode for output signals

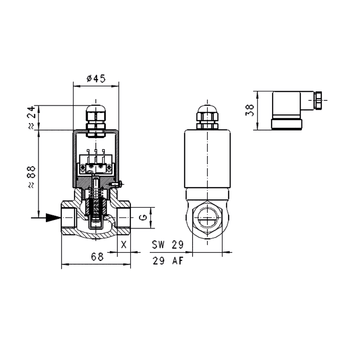

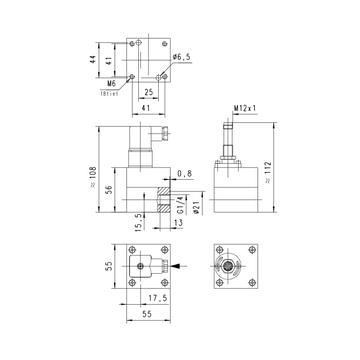

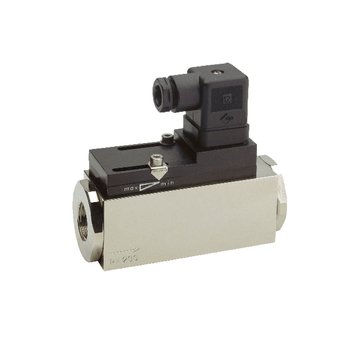

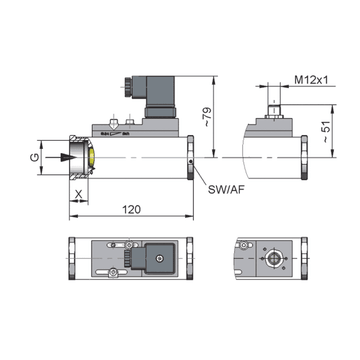

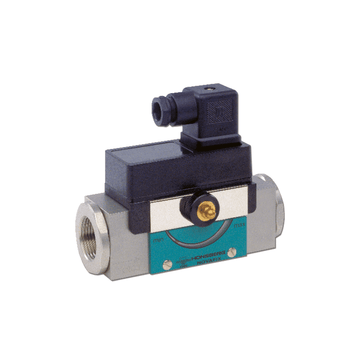

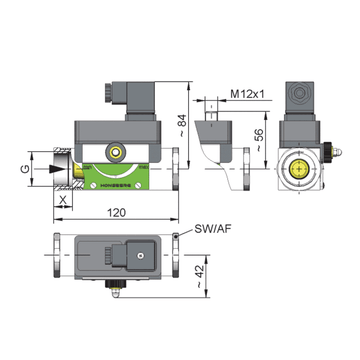

- Differential pressure measurement for non-aggressive gases

- Short reaction time

- Analog output, two switching outputs

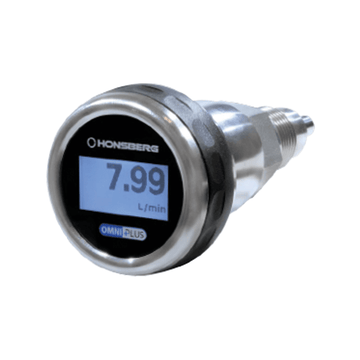

- Clear, easily legible, illuminated LCD display

- Designed for industrial use

- Small, compact construction

- Very simple installation

- Control panel assembly (IP65)

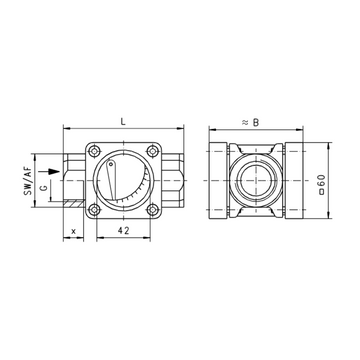

- Nominal pipe sizes 8mm to 40mm

- 0.4 - 90 l/min switching ranges

- 1/4” -1 1/2” BSP threaded connections

- Medium Temperature -20 °C to 110 °C

- 150 l/min max flow

- Lower Pressure Loss

- High temperature resistance

- Double-sided large-surface window

- Natural glass

- Visualisation of the flow rate

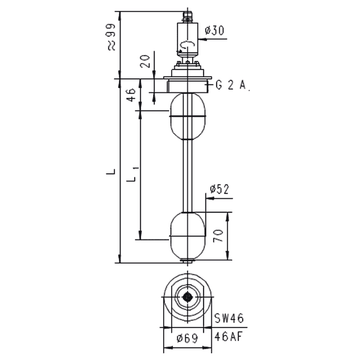

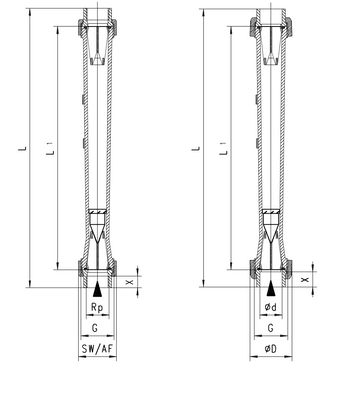

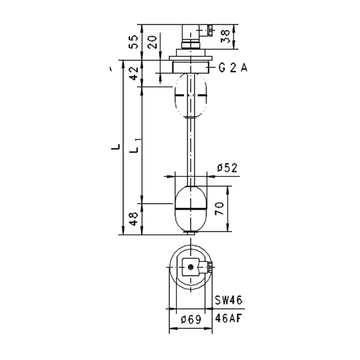

- Level Sensor with Reed chain

- Analogue output/switching output

- 250mm to 2000mm length options Very simple installation

- Various materials available

- Optional temperature sensor

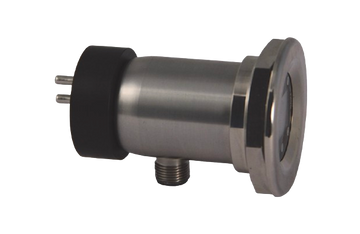

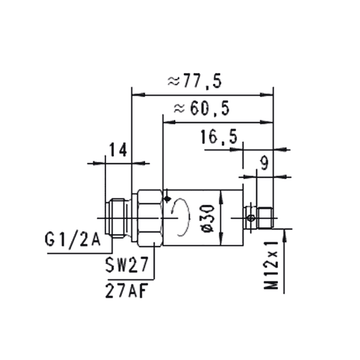

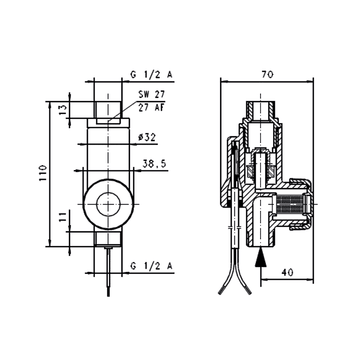

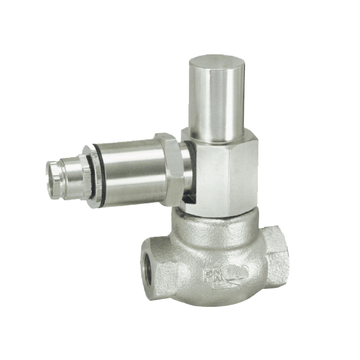

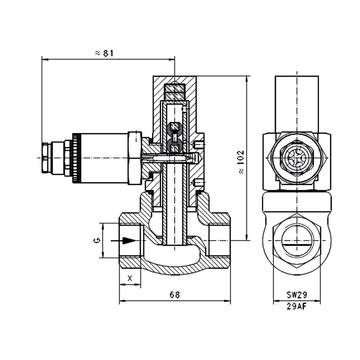

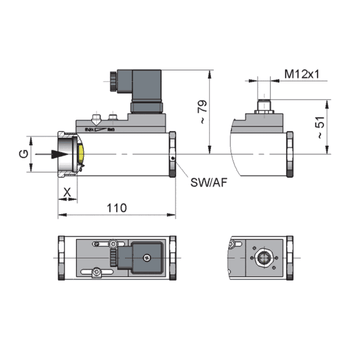

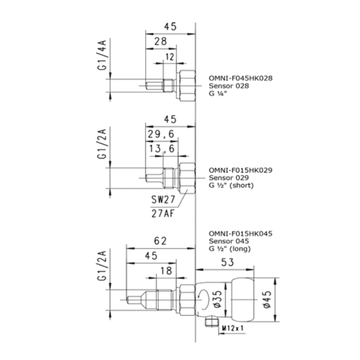

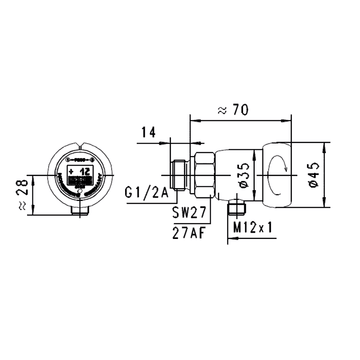

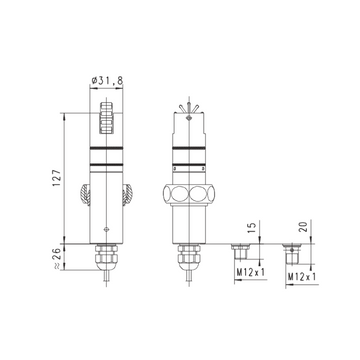

- Pressure Transducer With Switch

- Up to 400 bar pressure range

- Over-pressures up to 600 bar

- 4-20 mA or 0-10 V DC

- 1/2” BSP thread

- IP67 Rated

- Switching output and/or analogue output

|

Technical Datasheet |

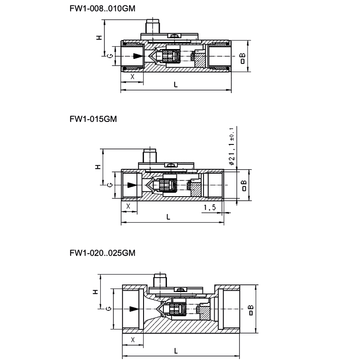

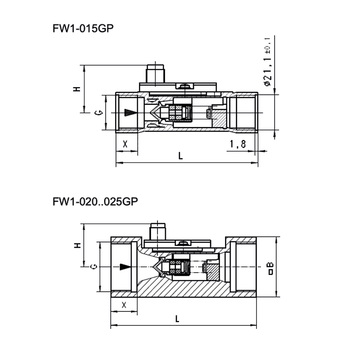

- Nominal pipe sizes 8mm to 15mm

- 0.4 - 12 l/min switching ranges

- 1/4” -1/2” BSP threaded connections

- Pressure up to 200 bar

- 20 l/min max flow

- High switching power

- High temperature resistance

- Double-sided large-surface window

- Natural glass

- Display of flow rate

- Rotor on both sides directly behind natural glass

- Installation location as desired

- Mechanical flow indicator

- With twin rotor for quantitative flow display

- Medium temperature 100°C

- Nominal pipe sizes 8-25 mm

- 1 - 11 l/min switching range

- 1/4” - 1” BSP threaded connections

- Not affected by dirt

- Brass connection material

- 230Vac/0.5A reed switch

- Nominal pipe sizes 15-25 mm

- 1 - 11 l/min switching range

- 1/2” - 1” BSP threaded connections

- Not affected by dirt

- Plastic connection material

- 230Vac/0.5A reed switch

- For 15 mm pipe size

- 1 l/min switching point

- 1/2” threaded connections

- Bi-directional flow switching

- Pressure up to 300 bar

- Viscosity stabilised

- For 15 mm nominal width

- 0.4-12 l/min switching range

- 1/2” male threads

- Integrated filter

- Plastic wetted parts

- Up to 10 bar pressure

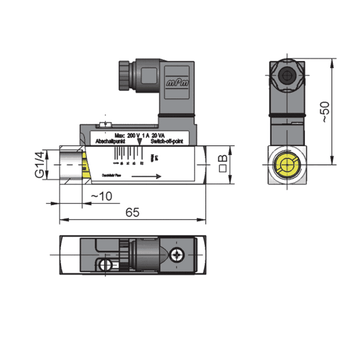

- Adjusted to switch between 0.015 and 0.4 l/min H2O

- Sizes from 1/4″ to 1/2″ BSP

- Low pressure loss design

- Bronze body

- Reed switch rated at 250Vac/1A 50VA

- Can be used with liquids and gases

- High precision and linearity

- For oils and other viscous media

- Ranges from 0.02 to 150 l/min

- Light and compact construction in an aluminium housing

- For cost-sensitive applications

- Suitable for both liquids & gases

- 3/8″ to 2″ BSP sizes

- Optional high & low switch points Optional 4 – 20mA transmitter

- Pressures up to 16 bar

- PVC or cast iron connections

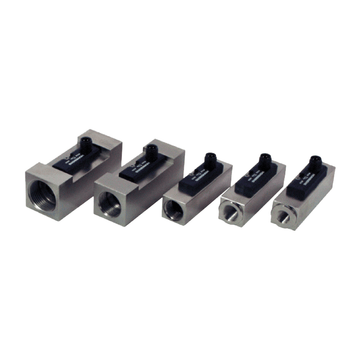

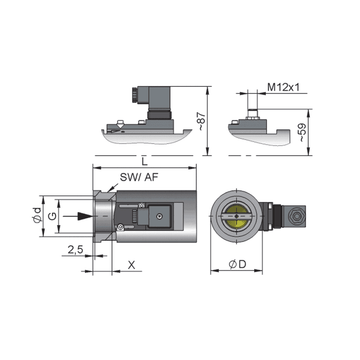

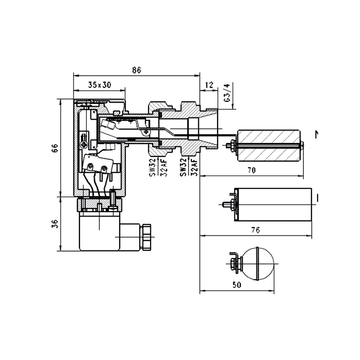

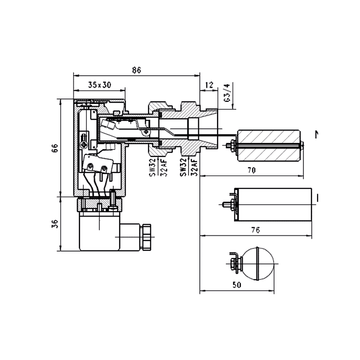

- Nominal pipe sizes 8-25 mm

- 0.1 - 80 l/min switching range

- 1/4” - 1” BSP threaded connections

- Optionally side or top displays

- Brass or stainless steel option

- Viscosity compensated version(HD2F)

- Nominal pipe sizes 8-25 mm

- 0.1 - 80 l/min switching range

- 1/4” - 1” BSP threaded connections

- Pressure 200 bar (500 bar option)

- Brass or stainless steel option

- Viscosity compensated version(HD2K)

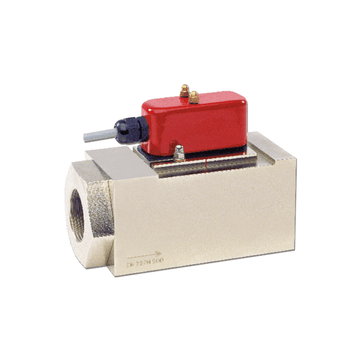

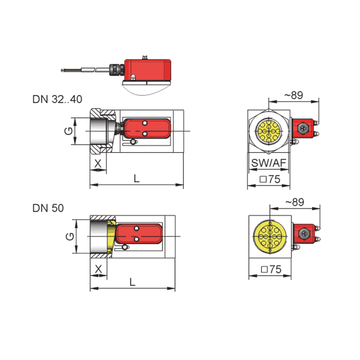

- For 32-50 mm pipe size

- 2-220 l/min switching range

- 1 1/4” - 2” threaded connections

- Brass or stainless steel option

- Pressure up to 200 bar

- Viscosity stabilised

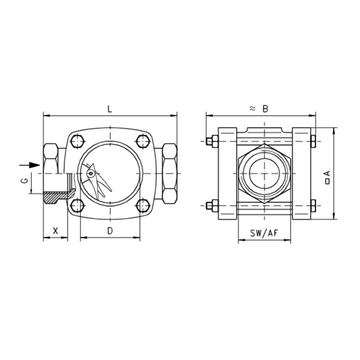

- Nominal pipe sizes 32-50 mm

- 10 - 150 l/min switching range

- 1 1/4” - 2” BSP threaded connections

- Pressure 200 bar

- Brass or stainless steel option

- Lower Pressure Loss

- Nominal pipe sizes 32-50 mm

- 15 - 80 l/min switching range

- 1 1/4” - 2” BSP threaded connections

- Pressure 200 bar

- Brass or stainless steel option

- Lower Pressure Loss

- Metal inserts up to 210 l/min.

- Media temperature up to 200°C

- Nominal widths DN 32 to DN 80

- Brass/stainless steel materials

- Male thread Installation location as desired

- No need for auxiliary power

- Metal insert up to 30 l/min.

- Media temperature up to 300°C

- Nominal widths DN 15 and DN 20

- Brass/stainless steel materials

- Optional installation

- No wear-parts

- No additional power supply

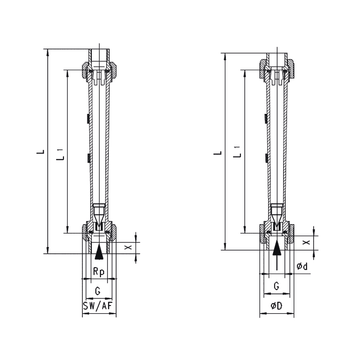

- From 0.4 to 100 l/min flow ranges

- Very fast response time

- High Overload Protection

- High Max Flow

- Low pressure Loss

- Compact Design

- 150c High Temperature Option

- 100 bar High pressure Version Available

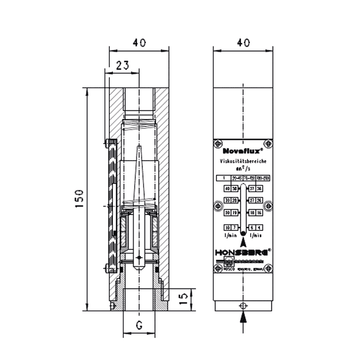

- Top Entry

- Materials combination may be selected

- Reed switch chain

- Suitable medium temperature -20..+105ºC

- Stainless Steel or Brass

- 4-20ma or 0-10v

- Switch Type: Reed switch

- Nominal Width: DN 8 to DN 25

- Pressure Loss: 0.4 to 1.4 bar at maximum flow (Qmax)

- Maximum Flow (Qmax): 80 l/min

- Tolerance: ±5% of full scale

- Pressure Resistance: Standard PN 200 bar, optional PN 500 bar

- Media Temperature: -20°C to +120°C

- Ambient Temperature: -20°C to +70°C

- Switching Voltage: Max 175 V DC / 120 V AC

- Switching Current: Max 0.25 A DC / 0.18 A AC

- Switching Capacity: Max 5 W / VA

- Protection Class: Class 2 (safety insulation)

- Ingress Protection: IP 65

- Standard brass bodied (stainless still available)

- 220Vac/5A Micro-switch

- 3/4” BSP thread

- SPDT C/O Micro-switch

- Brass or Stainless steel body

- Spansil (Buna) or stainless steel float

- Protected to IP65 with standard DIN

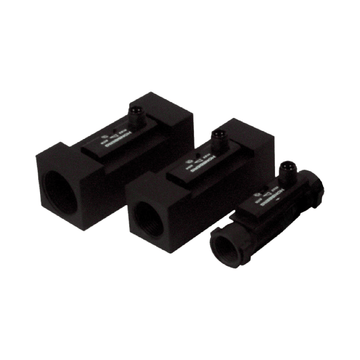

- Nominal pipe sizes 8mm to 25 mm

- 2 - 80 l/min switching ranges

- 1/4” -1” BSP threaded connections

- Maximum temperature 100 °C

- Viscosity stabilised option (NJV)

- Brass or Stainless Steel

- Screw-in-thread

- Brass/Stainless Steel materials

- Highly reproducible

- Normally open or normally closed contact

- ATEX approved

|

NW1 Level Switch Datasheet |

|

ATEX Switching Head A-U1-2 Datasheet |

- 220Vac/1A 50VA reed switch

- 3/4″ BSP thread

- Reed Switch N/O or N/C contacts depending on installation

- Brass or stainless steel body

- Spansil (Buna) or stainless steel float

- Protected to IP65 with standard Din plug

- PVDF float option

- 1/4” or 1/2” Screw in connection

- 2 - 150 cm/s metering range

- 4-20 mA or 0-10V output

- PNP / NPN switch output

- All stainless wetted parts

- Fast response times

- Simple filling counter with programmable end signal

- Control switchover at present value

- Automatic, dynamic change of display unit and decimal places in the graphics display

- Simple guided menu via graphics display

- Momentary value indicator and totalisation

- Pulse output with adjustable pulse per volume

- Antivalent outputs

- Analogue output of the momentary value

- Simple guided menu via graphics display

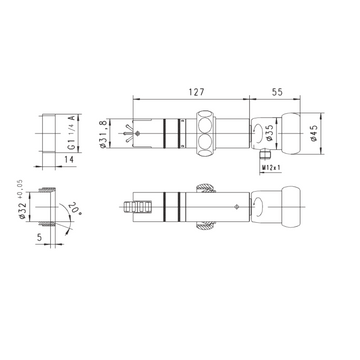

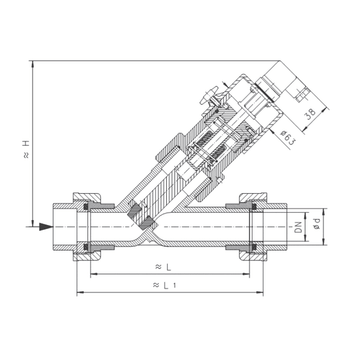

- Flow transmitter with display

- For pipe diameters of DN 32 or larger

- Stainless steel version

- Suitable for retrofitting in existing pipelines with tapping clamps

- Analog output 4..20 mA or 0..10 V

- Two programmable switches

- Selectable units in the display

- Parameter change with rotating ring

- Electronics housing with non-scratch, chemically resistant glass

- Rotatable electronic housing for best reading position

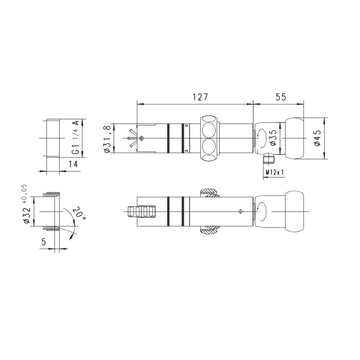

- Flow transmitter with display

- For pipe diameters of DN32 or larger

- Plastic version

- Suitable for retrofitting in existing pipelines with tapping clamps

- Analog output 4..20 mA or 0..10 V

- Two programmable switches

- Selectable units in the display

- Parameter change via rotating ring

- Electronics housing with non-scratch, chemically resistant glass

- Rotatable electronic housing for best reading position

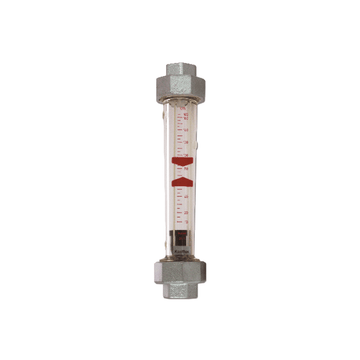

- Easy to fit to existing pipework

- Sizes from 1/4″ to 2″ BSP

- Large glass area allow viewing from any direction

- Maximum pressure 6 bar

- Maximum temperature 70°C

- Brass body

- Nominal pipe sizes 10mm to 80mm

- 2 - 500 l/min switching ranges

- Screw Connection with socket

- Medium Temperature -20 °C to 60 °C

- 250 l/min max flow

- No contact switching

- All plastic (POM or PVDF) flow indicator

- Can be installed in any position

- Low ‘start-up’ benefit due to low friction design

- 3/8″ and 1″ BSP sizes

- Maximum pressure 16 bar

- Maximum temperature 60ºC

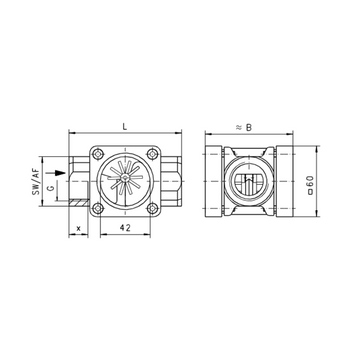

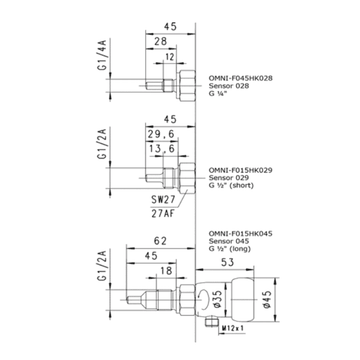

- Nominal width: DN 8.0.25

- Process connection: female thread G 1/4..G 1

- Display range: 0.7..60 l/min

- Pressure loss: up to 0.7 bar

- Pressure resistance: up to 0.7 bar

- Pressure resistance: PN 16 bar

- Paddle wheel measuring principle

- Stainless steel housing (1.4305)

- For pipe sizes DN32 and up

- Output options: T, I, U, F, S IP67 protection rating

- Flow range 0.3–6 m/s ±1% reproducibility

- Max media temp up to 95 °C

- PN10 pressure rating

- CE compliant

- Paddle wheel measuring principle

- Lightweight plastic housing (PVC)

- For pipe sizes DN32 and up

- Output options: PNP, NPN, NAMUR, I, U, F, S

- IP67 protection rating

- Flow range 0.3–6 m/s

- ±1% reproducibility

- Max media temp 60 °C

- PN10 pressure rating

- CE compliant

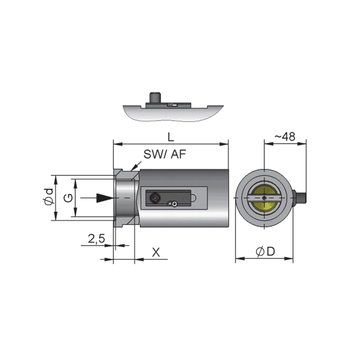

- 8mm pipe size

- 0.04 - 3 l/min switching range

- 1/4” threaded connections

- Pressure up to 350 bar

- Brass or stainless steel option

- -20..+100 °C optionally 160 °C

- High precision and linearity

- For oils and other viscous media

- Ranges from 1.5 to 2500 l/min

- Connection G 1..G 21 /2

- Very low dependence on viscosity

- Can be used up to 40,000 mm²/s (cSt)

- Linear frequency output (push-pull)

- Light and compact device (aluminium housing)

- Operation and measurement possible with forwards and reverse flow

- For cost-sensitive applications