CS Instruments

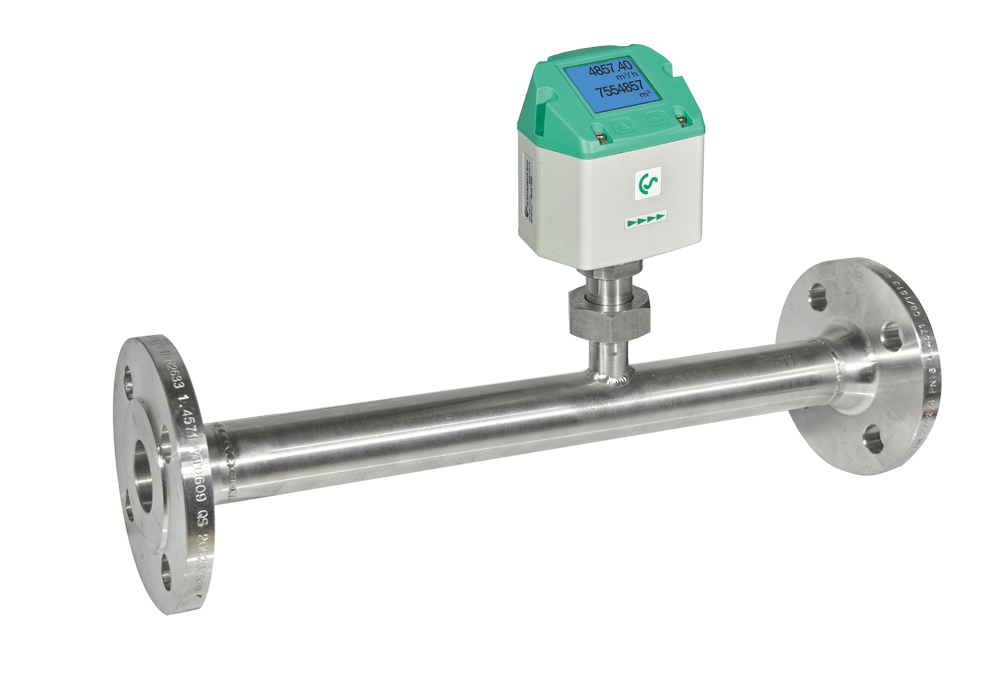

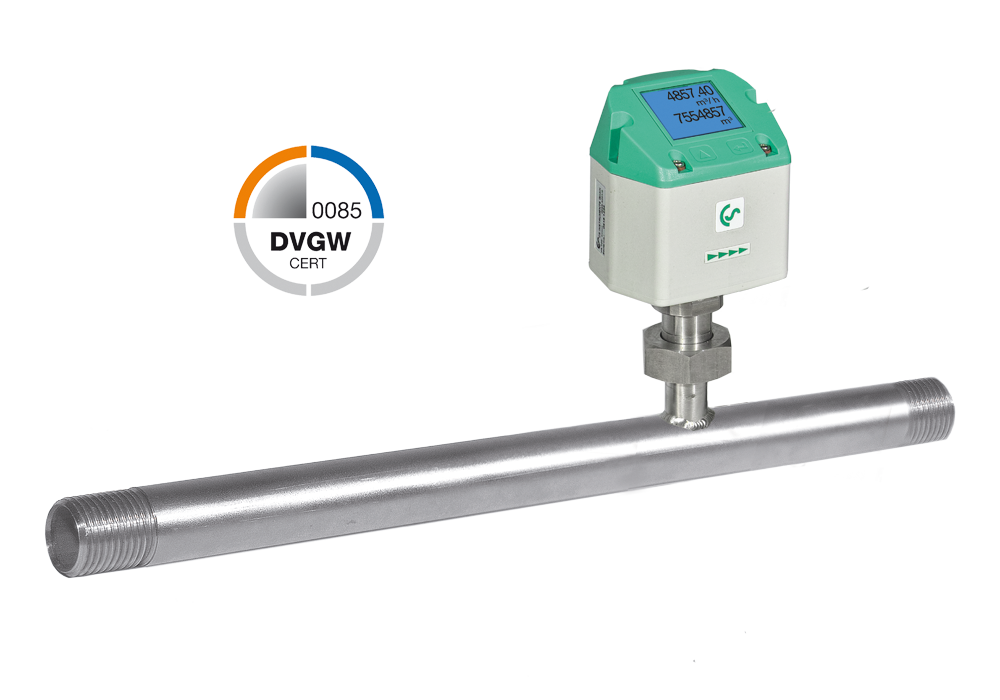

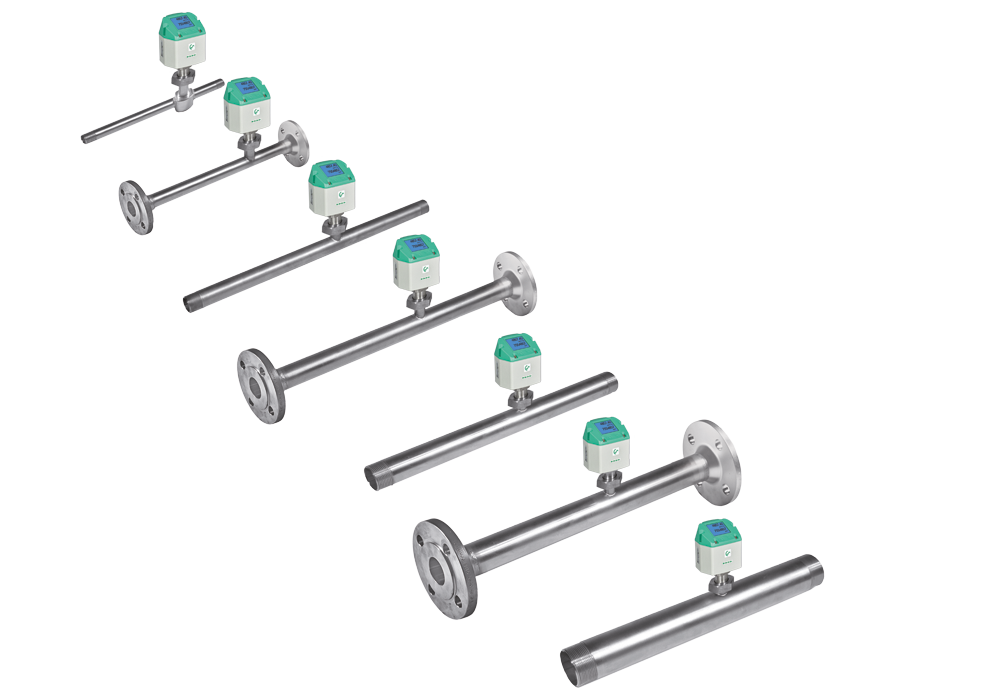

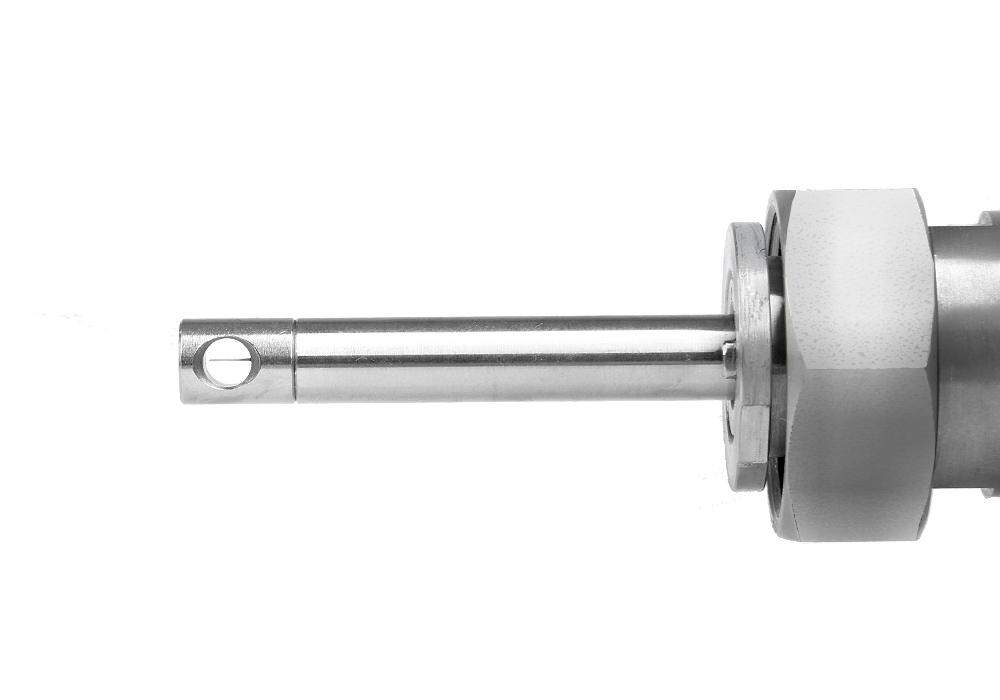

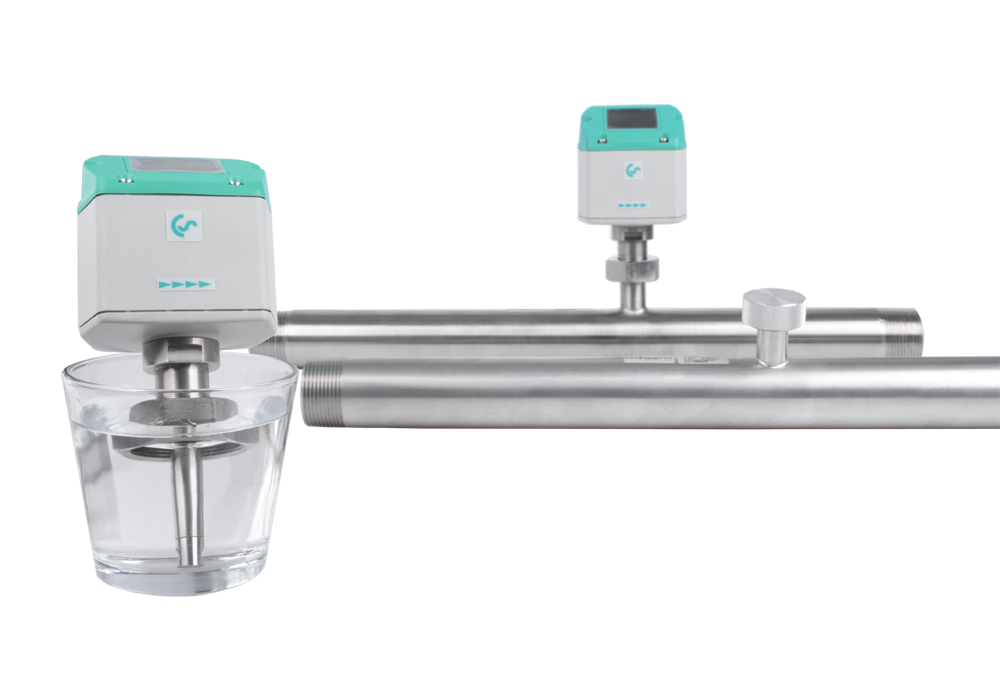

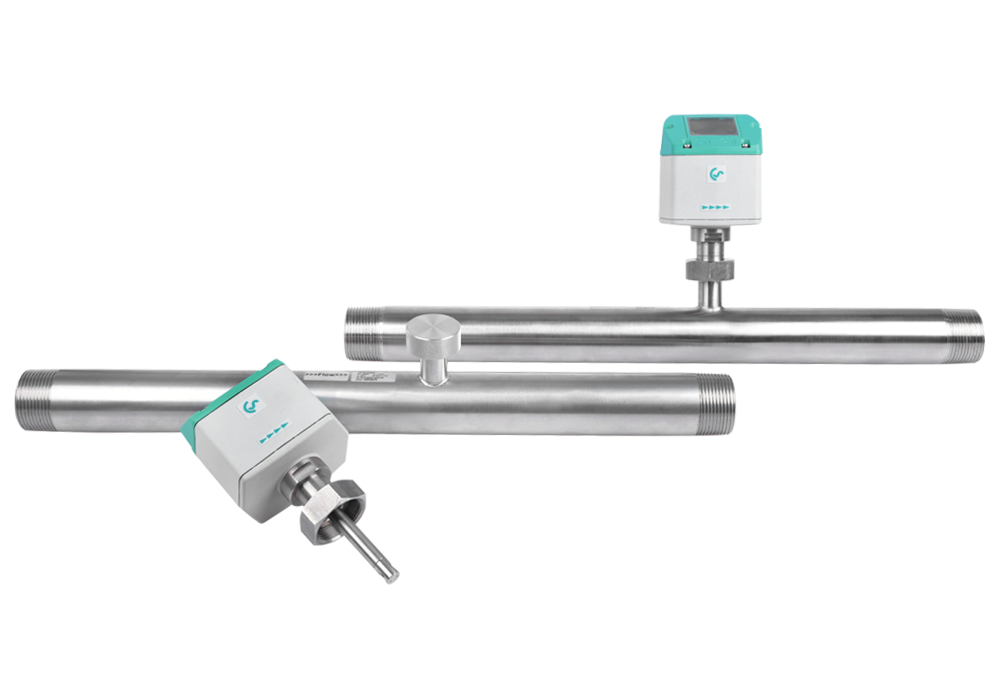

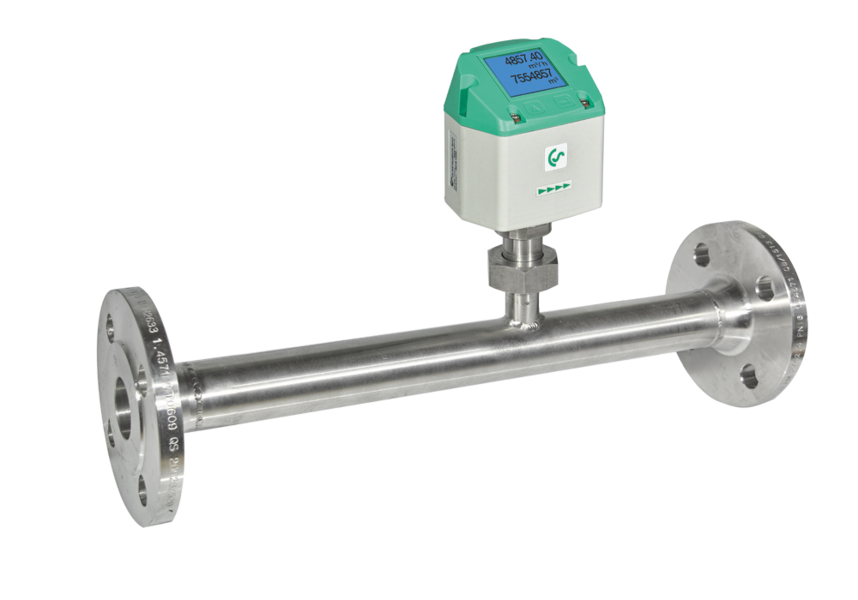

VA 520 - Thermal Mass Flow Meter for Flow Measurement

- Pressure Range Up to 40 Bar

- Temperature Range From -30 to 80°c

- Protection Class IP65 Integrated Display to Show the Measured Values

- Can Be Used From Dn 8 to Dn 80

- Settings Adjustable via the Keys of the Display

- Main Counter Reading Can Be Reset via the Display

- For Velocities Up to 224 Nm/s

£0.00

In Stock

Sold out