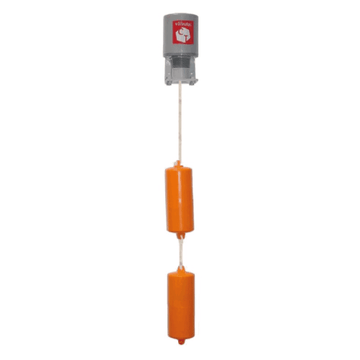

Float Switches

Float switches stand as indispensable sentinels in the vast sea of electrical components, silently guarding against floods and spills with their simple yet ingenious design. These unassuming devices are ubiquitous in various industries, from residential sump pumps to industrial water tanks, offering a reliable liquid-level monitoring solution.

But what exactly are float switches, and how do they function? 🧐

How Does a Float Switch Work

Float switches operate on a remarkably straightforward principle: buoyancy. Picture a miniature buoy floating atop the water's surface, tethered to a switch below. The float follows suit as the liquid level rises or falls, triggering the switch to open or close a circuit. This action sends signals to pumps, alarms, or control systems, orchestrating the necessary response to maintain optimal fluid levels.

Transitioning from open to closed circuit, or vice versa, the float switch's movement dictates the electrical continuity, effectively acting as a gatekeeper for liquid management systems. This inherent simplicity lends float switches a robustness and reliability that transcends their humble appearance.

How to Check the Float Switch

Float switches require periodic maintenance and inspection, like any mechanical device, to maintain their efficacy. Fortunately, verifying the functionality of these devices is a relatively straightforward process. Begin by visually inspecting the float switch for any signs of physical damage or obstruction. Ensure that the float moves freely along its vertical path without impediment. Next, simulate the rising and falling of liquid levels by manually manipulating the float. Listen for the distinct click of the switch as it transitions between states, indicating proper functionality. Additionally, testing the electrical continuity with a multimeter provides a quantitative assessment of the switch's performance, affirming its reliability in real-world applications.

Additionally, consider the environmental conditions and the nature of the liquid being controlled. Harsh chemicals or abrasive materials may degrade the switch over time, necessitating more frequent inspections and replacements. By adhering to a regular maintenance schedule, you can prolong the lifespan of float switches and minimise downtime.

Float Switches in Submersible Pumps

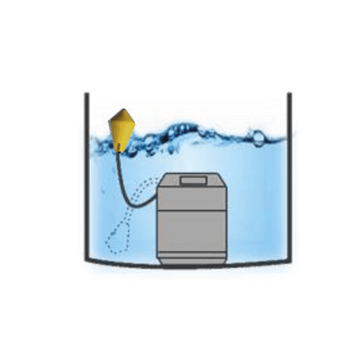

Submersible pumps, designed to operate submerged in fluid, rely heavily on float switches for efficient and reliable performance. In these applications, float switches are crucial in monitoring liquid levels and controlling pump operation. Installed within the pump's housing or attached to the pump via a rope, float switches serve as the eyes and ears of the system, ensuring optimal functionality even in challenging environments.

When the liquid level rises above a certain point, the float switch activates the pump, removing excess fluid and preventing flooding or overflow. Conversely, when the liquid level drops below a specified threshold, the float switch signals the pump to shut off, preventing damage from running dry. This dynamic interplay between float switches and submersible pumps exemplifies the synergy of technology and innovation, resulting in efficient fluid management solutions.

Navigating Smooth Waters with Float Switches

Float switches reign supreme in the realm of liquid level monitoring, offering a dependable solution to an age-old challenge. Their elegant design and unwavering functionality make them indispensable across various residential and commercial industries. By understanding the mechanics of float switches and adhering to regular maintenance protocols, one can ensure smooth sailing amidst fluctuating liquid levels.

PVL Float Switches

Pressure Vacuum Level Ltd has been selling high-quality float switches for over 28 years. PVL provides these devices for various industries. Don't hesitate to contact us if you have any questions about our pressure switches or other products.

Other Products

PVL customers can rely on us for high-quality products. Float Switches are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Pressure Switches and Vacuum Switches.

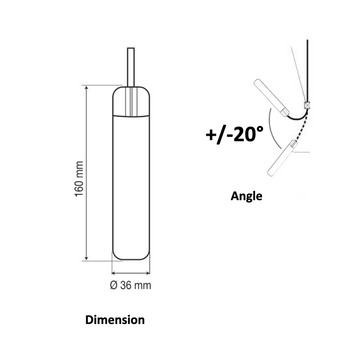

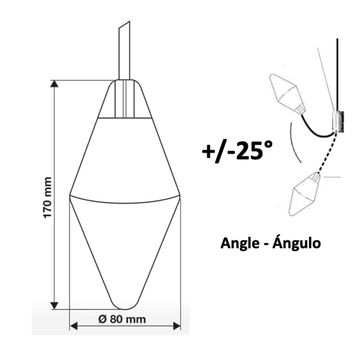

- Omni Directional Operation

- Switching angle+/- 25º

- Maximum pressure 3.5 bar

- Allowed Fluid Density 0.70 to 1.15

- 16A resistive - 6A inductive

- 6m, 13m, 15m, 20m, 25m Sizes Available On Request

|

Technical Datasheet |

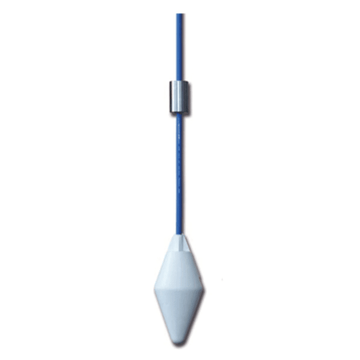

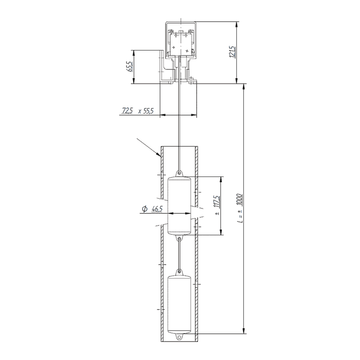

- Allowed fluid densities: 0,75 à 1,50 g/cm³

- Electric characteristics: 250 VCA - 50/60 Hz

- Cut-out power: 12 (6) A

- Maximum pressure: 5,5 bars

- Maximum temperature: 85 °C

- Protection index IP 68

- Housing: Copolymer polypropylene

- Type of cable: Neoprene

- Float weight without cable: 60 g

|

Technical Datasheet |

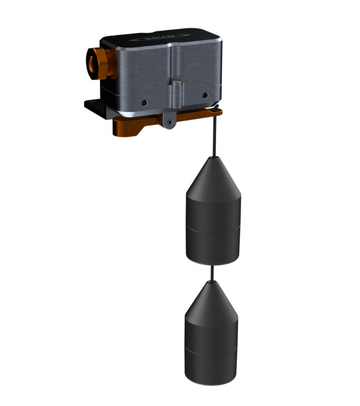

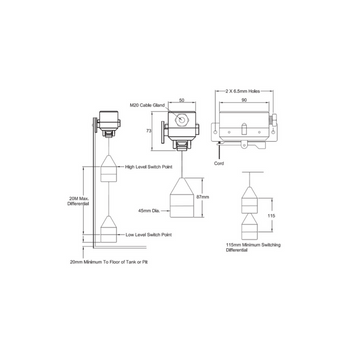

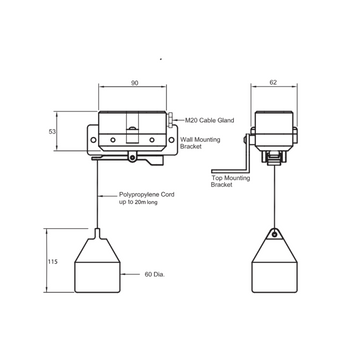

- Australian Made

- High and Low Level Control

- 2 HP 1.5kW 20 AMP 500V S.P.D.T switch

- No metal parts in contact with liquids

- Heavy duty all metal housing

- Weatherproof to IP67

- Super reliable magnetic action

|

Technical Datasheet |

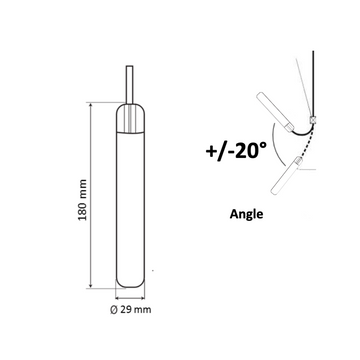

- Omni Directional Operation

- Switching angle+/- 20º

- Maximum pressure 5.5 bar

- Allowed Fluid Density 0.70 to 1.15

- 12A resistive - 6A inductive

- 2, 3, 5, 10 and 20m Options

|

Technical Datasheet |

- 5 to 500V AC 15A 1.5kW (2HP)

- Switch Gold Contact Low Wetting Current model available No metal parts in contact with liquids

- 60mm level change on to off or off to on

- Highly reliable magnetic action

- Fully sealed IP67 electrical housing

- M20 cable gland built in

- Omni Directional Operation

- Switching angle+/- 110º

- Maximum pressure 3.5 bar

- Allowed Fluid Density 0.70 to 1.15

- 20A resistive - 8A inductive

- 1, 3, 5, 10 and 20m Options

- Allowed fluid densities: 0,70 à 1,15 g/cm³

- Electric characteristics: 12,24,48 VCA /VCC - 250 VCA - 50/60 Hz

- Cut-out power: 16 (6) A Maximum pressure: 3,5 bars

- Maximum temperature: 85 °C

- Protection index: IP 68

- Omni Directional Operation

- Switching angle+/- 25º

- Maximum pressure 4 bar

- Allowed Fluid Density 0.70 to 1.15

- 16A resistive - 6A inductive

- 5, 10, 13, 15, 20, 25 and 30m Options

|

Technical Datasheet |

- Aggressive liquids : acids, solvents, corrosive liquids, hydrocarbons, sea water, etc.

- Level control of multiple pumps

- Emptying / Filling function

- Overflow or dry-running protection

- High / low level alarm

- Clear, clean liquids, rain water

- Wastewater, sewage water, charged liquids

- Slightly aggressive liquids (oils, mud, paint, etc.) and more aggressive liquids if equipped with a HR HY cable

- Level control of multiple pumps

- Overflow or dry-running protection

- High / low level alarm

- Hi/ Lo 2 position synthetic resin floats

- 2 contacts… 1x normally open/ 1x normally closed

- 1 meter cable

- Single phase

- Voltage 110- 220V

- Current15 A

- Power 1,5 Kw (2 HP)