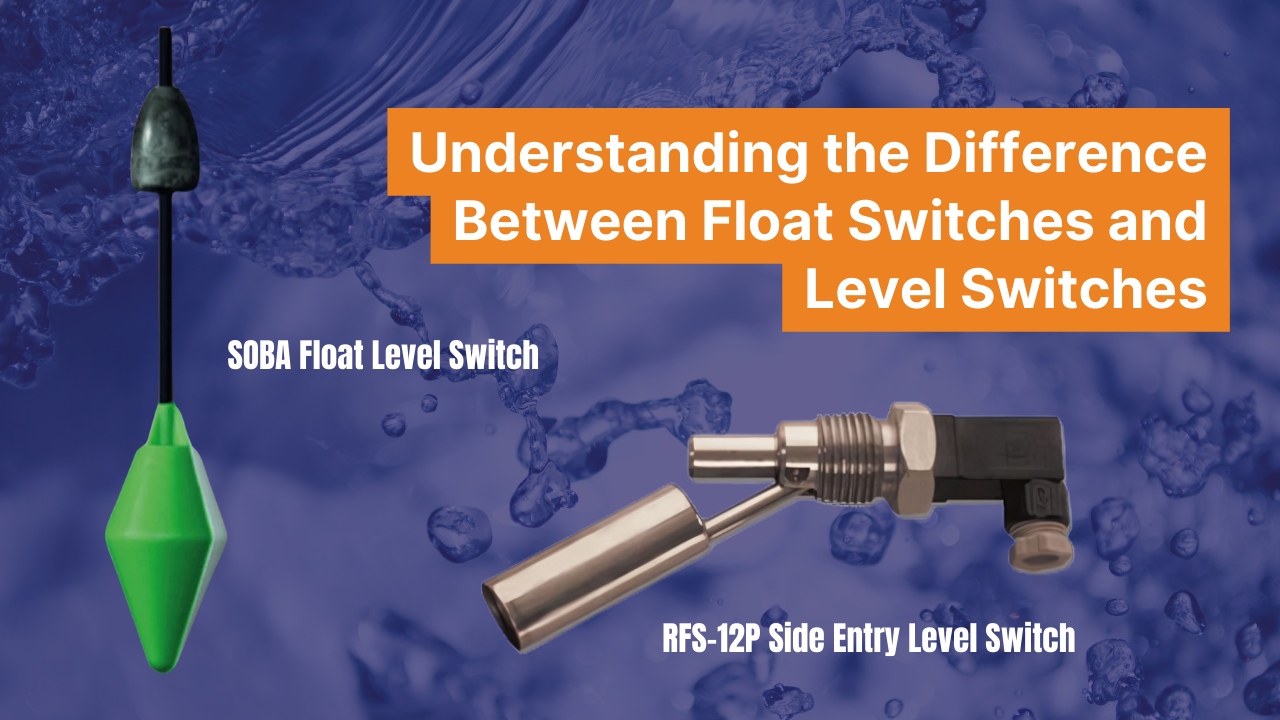

Understanding the Difference Between Float Switches and Level Switches

When it comes to liquid level monitoring and control, float switches and level switches are two commonly used devices. Although they serve similar functions, they operate in different ways and are suited to different applications. Understanding these differences is crucial for selecting the right device for your specific needs. This blog post delves into the distinctions between float switches and level switches, examining their functionalities, applications, and advantages.

Introduction to Float Switches and Level Switches

Float switches and level switches are essential components in many industries, including water treatment, oil and gas, and manufacturing. They are designed to detect the presence or absence of liquid at a certain level within a tank or container. While both types of switches perform the same basic task, their mechanisms and applications vary significantly.

Float Switches

Float switches are simple devices that detect the liquid level using a floating object. The float rises and falls with the liquid, and its movement triggers a switch mechanism to signal the presence or absence of liquid. Float switches are typically used in applications where precise level measurement is not critical but where liquid level detection is essential.

Float switches come in various designs, including vertical and horizontal types. Vertical float switches are mounted at the top or bottom of a tank and move up and down with the liquid level. Horizontal float switches are mounted on the side of a tank and swing in and out with the liquid level. Both types are relatively easy to install and maintain.

How Float Switches Work

The working principle of float switches is based on buoyancy. A float, made of a material less dense than the liquid it is monitoring, is attached to a rod or chain. As the liquid level changes, the float moves accordingly. This movement either opens or closes an electrical circuit, providing a signal that can be used to control pumps, alarms, or other devices.

Float switches are commonly used in applications such as sump pumps, sewage systems, and industrial processes where it is necessary to monitor and control liquid levels. They are particularly useful in situations where the liquid is corrosive or contains solids, as the float can be made from materials resistant to these conditions.

Advantages of Float Switches

One of the primary advantages of float switches is their simplicity. They are straightforward to install and require minimal maintenance. Additionally, float switches are highly reliable and can operate in harsh environments. Their mechanical design makes them less susceptible to electronic interference, which is a common issue in industrial settings.

Another advantage is the cost-effectiveness of float switches. Due to their simple construction, float switches are generally less expensive than more complex level sensing devices. This makes them an attractive option for applications where budget constraints are a concern.

Level Switches

Level switches, on the other hand, use various technologies to detect liquid levels. These technologies include ultrasonic, capacitive, and conductive sensing methods. Level switches are more sophisticated than float switches and are often used in applications where precise level measurement is crucial.

Ultrasonic level switches use sound waves to detect the liquid level. A transducer emits ultrasonic waves that bounce off the liquid surface and return to the sensor. The time it takes for the waves to return is used to calculate the liquid level. Capacitive level switches, on the other hand, measure changes in capacitance caused by the presence of liquid between two conductive plates.

How Level Switches Work

The operation of level switches depends on the technology used. Ultrasonic level switches rely on the principle of sound wave reflection. When the liquid level changes, the time it takes for the sound waves to travel from the transducer to the liquid surface and back changes as well. This time difference is used to calculate the liquid level accurately. Capacitive level switches work by measuring the capacitance between two conductive plates. When the liquid level rises or falls, the dielectric constant between the plates changes, altering the capacitance. This change is detected and used to determine the liquid level. Conductive level switches, meanwhile, use the conductivity of the liquid to complete an electrical circuit, signaling the presence of liquid.

Advantages of Level Switches

Level switches offer several advantages over float switches. One of the most significant advantages is their ability to provide precise and accurate level measurements. This is particularly important in applications where maintaining a specific liquid level is critical, such as in chemical processing or pharmaceutical manufacturing.

Another advantage of level switches is their versatility. With various sensing technologies available, level switches can be used in various applications, including those involving hazardous or corrosive liquids. Additionally, level switches often have no moving parts, reducing the risk of mechanical failure and increasing reliability.

Applications of Float Switches

Float switches are commonly used in applications where simplicity and cost-effectiveness are paramount. For example, they are often used in residential and commercial sump pump systems to prevent flooding. The float switch detects rising water levels and activates the pump to remove excess water.

In industrial settings, float switches are used in storage tanks to monitor liquid levels and control pumps or valves. They are also used in sewage treatment plants to control the operation of pumps and other equipment based on the level of wastewater. Their ability to operate in harsh conditions makes them ideal for such applications.

Applications of Level Switches

Level switches are used in applications requiring precise level measurement and control. For instance, in the chemical industry, level switches are used to monitor and control the level of chemicals in storage tanks and reactors. Accurate level measurement is essential to ensure the proper mixing and reaction of chemicals.

In the food and beverage industry, level switches are used to monitor the level of liquids in processing tanks and containers. Maintaining the correct liquid level is crucial to ensure the quality and consistency of the final product. Level switches are also used in the oil and gas industry to monitor the level of oil and other fluids in storage tanks and pipelines.

Choosing the Right Switch for Your Application

When choosing between a float switch and a level switch, several factors need to be considered. The most important factor is the level of precision required. If precise level measurement is not critical, a float switch may be the best option due to its simplicity and cost-effectiveness. However, if accuracy is essential, a level switch with the appropriate sensing technology should be chosen. Another factor to consider is the nature of the liquid being monitored. If the liquid is corrosive or contains solids, it is essential to choose a switch made from materials that can withstand these conditions. Additionally, the operating environment should be considered. Float switches are generally more robust and can operate in harsh conditions, while level switches may require more protection from environmental factors.

Conclusion

In conclusion, float switches and level switches are both valuable tools for monitoring and controlling liquid levels. Float switches are simple, cost-effective devices suitable for applications where precise measurement is not critical. Level switches, on the other hand, offer greater accuracy and versatility, making them ideal for applications requiring precise level control. Understanding the differences between these two types of switches is essential for selecting the right device for your specific needs.