Temperature Transducers

A temperature transducer is used to measure a physical object's temperature. A transducer is a device that converts a physical quantity into electrical energy. As a result, a temperature transducer is a device that converts the thermal energy of substances into electrical form. In other words, it is a piece of electrical equipment used for automated temperature measurement. The temperature transducer's primary function is to measure the material's heat in a readable format.

Features of Temperature Transducers

Although temperature transducers come in various shapes and sizes, their basic principles and characteristics are quite similar and can be summarised as follows:

- The thermal quantities are always the input to a temperature transducer.

- They frequently convert thermal amounts to electrical amounts, which are then used to calculate temperature and heat flow.

Temperature transducers convert thermal energy into physical quantities such as mechanical energy, pressure, and electrical impulses. Using Industrial Tools Requires the Use of a Temperature Transducer.

Why Do We Use Temperature Transducers?

Temperature transducers ensure that a process stays within a specified range, provides safe application usage, or satisfies a mandated requirement when dealing with extreme heat, risks, or inaccessible measurement sites.

PVL Temperature Transducers

Pressure Vacuum Level Ltd has been selling high-quality temperature transducers for over 28 years. PVL provides these devices for various industries.

Don't hesitate to contact us if you have any questions about our temperature transducers or other products.

Other Products

PVL customers can rely on us for high-quality products. Temperature Transducers are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Temperature Sensors and Pressure Sensors.

- Using BLE5 (Bluetooth® Low Energy), connect to smart phones and tablets

- Pressure ranges from Vacuum to 10,000 psi

- Long battery life

- 1% Accuracy with optional .25% ultra high accuracy

- Stainless steel wetted parts and high impact polycarbonate construction

- Alarm set points

- Secure field programmable naming

- Patent pending design

- Schrader, NPT, SAE and G ¼ pressure connection

|

Technical Datasheet |

- Low Cost

- Vac Ranges to +285 psi

- Pressure Ranges 0 to 3 psi up to 10,000 psi

- Compact Design

- 316 Stainless Steel Housing

- All Stainless Steel Wetted Parts

- High 125° C (257° F) Operating Temperature

- 0.4% Accuracy

- Custom Outputs and Ranges Available

- OEM Tested & Approved

- Low Power Consumption

- Low Cost

- Wide Temperature

- Measurement Range

- Industry Standard Analog Outputs

- 316 Stainless Steel Wetted Parts

- Excellent Long Term Stability

- OEM Tested and Approved

- Thermoelements J, K, S

- Pt100 Elements

- 0/2..10 V und 0/4..20 mA

- 4..20 mA analogue output

- Transmitter for electrical signals

- Universal input for standard signals, Pt100, thermocouple, potentiometer

- Configuration via front-side DIP switch

- Wide-range power supply or 24 V DC

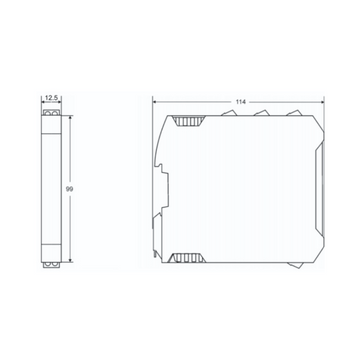

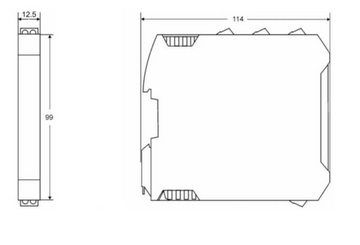

- Housing width 12.5 mm

- Removal coded screw terminals

- Carrier rail mounting TS35 EN60715

- Thermoelements J, K, S

- Pt100 / Pt1000 / NTC resistance measurement

- 4..20 mA analogue output

- Universal input for Pt100, Pt1000, thermocouple, NTC and resistance measurement value

- Configuration via front DIP switches

- Analog actual value output 4 .. 20mA

- Zero point and limit value can be adjusted via trim potentiometers on the front

- Wide-range mains adapter or 24 V DCa

- Optional supply via carrier rail bus

- Removable coded screw terminals or optional push-in terminals

- Housing width 12.5 mm

- Carrier rail mounting TS35 EN60715