Flow Limiters

A flow limiter decreases water flow rate in home or industrial applications. They are positioned in the flow path, effectively decreasing the water's travel space. This reduces the flow output; for example, a 5 litre per minute flow rate is lowered to a 2 litre per minute.

What Do Flow Limiters Do?

Flow limiters act as a barrier to the flow, reducing the area to travel through. This reduces the flow output, resulting in fewer litres per minute emitted by the pipe or hose. Slowing down the flow rate reduces the overall amount of water used per minute.

How Do Flow Limiters Work?

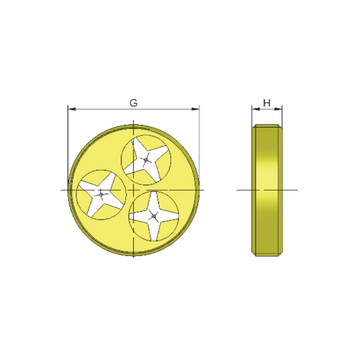

Two stainless steel spring plates crosswise mounted and riveted together in our industrial flow limiters achieve constant flow. As the differential pressure fluctuates, the space between the spring-loaded stainless-steel plate and the seal-surface changes continually. The gap expands as the differential pressure falls and closes as the pressure increases, resulting in a constant flow volume through the device.

Where are Industrial/Commercial Flow Limiters Used?

- Fluid Metering, Controlling Flow Throughput

- Actuator, Cylinder, or Motor Speed Control

- Inkjet Printing

- Medical Applications

- Chilled Water Balancing

- Semiconductors

- Reverse Osmosis Systems

- Water Flow Regulation for Stills

- Food and Beverage

PVL Flow Limiters

Pressure Vacuum Level Ltd has been selling high-quality flow limiters for over 28 years. PVL provides these devices for various industries.

Don't hesitate to contact us if you have any questions about our flow limiters or other products.

Other Products

PVL customers can rely on us for high-quality products. Flow Limiters are only a handful of the products we provide customers across the United Kingdom. We are also a significant supplier of Pressure Switches and Transducers.

- Metal insert up to 30 l/min.

- Media temperature up to 300°C

- Nominal widths DN 15 and DN 20

- Brass/stainless steel materials

- Optional installation

- No wear-parts

- No additional power supply

- Metal inserts up to 210 l/min.

- Media temperature up to 200°C

- Nominal widths DN 32 to DN 80

- Brass/stainless steel materials

- Male thread Installation location as desired

- No need for auxiliary power