Calorimetric

A flow monitor, also known as a calorimetric flow switch, is often used to detect flow in a pipe system. Calorimetric flow switches, also known as thermal flow monitors, use physical heat transfer principles in flows. Continuous heating and regulated heating are the two kinds of technical solutions.

A flow switch based on the concept of calorimetric measurement is made up of a measuring probe and two temperature sensors. One of the sensors is heated continuously by a wire-wound integrated heating element with constant heating power and measures the temperature at the heating element.

Continuous heating

The second sensor measures the temperature of the media in the pipe. As a consequence, a temperature difference between the two sensors occurs, which the electronics detect. The smaller the temperature difference, the faster the medium in the pipeline flows. The cooling effect of the flowing medium acts as the basis for this. The molecules in the medium that flow past the probe tip collects and transmit "heat packets." The faster the rate of molecular movement, the greater the cooling effect. The number of molecules passing through increases inexorably as flow velocity increases.

Regulated heating

The measuring probe has a nearly similar design: The medium is equipped with two temperature sensors, one of which may be heated. However, in this technical method, the heating power is regulated such that the temperature difference between the two temperature sensors stays constant throughout. Consequently, as the flow velocity increases, so must the heating power to maintain the size of the temperature difference. As a result, the applied heating power is a direct measure of the flow velocity of the medium.

Got a question?

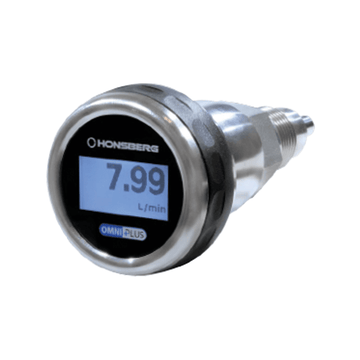

Do you have any more questions regarding the measuring principle behind the calorimetric flow switch, or do you require help choosing one? PVL's portfolio includes three calorimetric flow switches for monitoring the flow of liquid. We’ll be more than happy to help you.

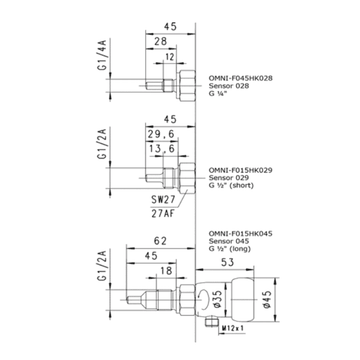

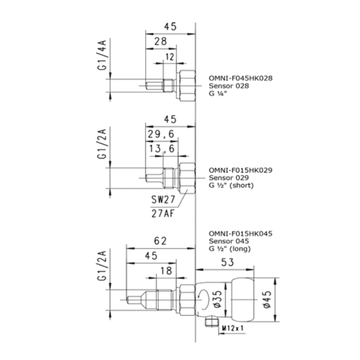

- 1/4” or 1/2” Screw in connection

- 2 - 150 cm/s metering range

- 4-20 mA or 0-10V output

- PNP / NPN switch output

- All stainless wetted parts

- Fast response times