Float Valves

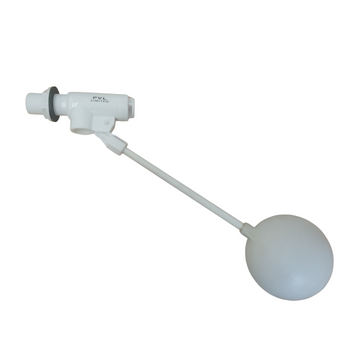

Float valves, also known as ballcocks, are indispensable devices for regulating fluid levels in tanks across various industries. Float valves are used in diverse industries, from toilet tanks to industrial basins and swimming pools. Their simplicity and reliability make them ideal for remote installations with impractical electrical control, such as watering troughs.

Float materials range from polypropylene to stainless steel, with weighted variants optimising performance in vertical-rod systems. Float valves are pivotal in maintaining precise fluid levels in tanks across numerous industries.

- Fully Adjustable Arm Positions

- Robust Construction

- Simple to Install

- Standard and Large Bore Orifice

- No Tools Required to Adjust the Ball

- Cost Effective Tank Level Control

- Seals EPDM

|

Technical Datasheet |

- 10mm to 65mm port diameter

- 3/8” to 2 1/2” BSP connection

- All 316 stainless steel

- Flow rates up to 75,966 litres per hr

- Rated up to 10 Bar

- Silcon seal (others available)

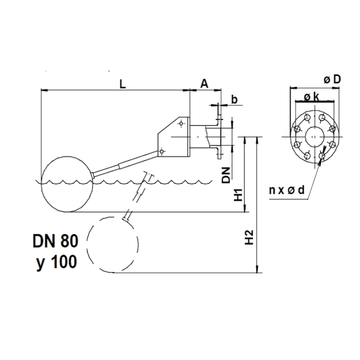

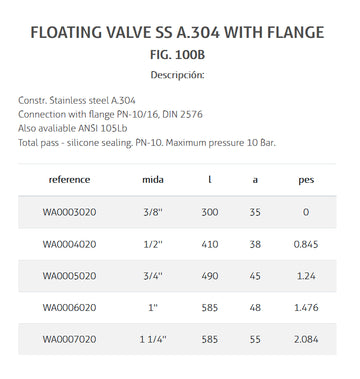

- AISI 316 Stainless Construction

- PN16/10 Flange Connection DIN 2576. Optional ANSL 150LB

- Total Step - Silicone Closure. Pn-16

- Maximum Pressure 10 bar

- 10mm to 80mm port diameter

- 3/8” to 4” BSP connection

- 304 (100) or 316 (200) stainless steel

- Flow rates up to 291,714 litres per hr

- Rated up to 10 Bar

- Silcon seal (others available)

- 10mm to 80mm port diameter

- 3/8” to 4” BSP connection

- 304 (100) or 316 (200) stainless steel

- Flow rates up to 291,714 litres per hr

- Rated up to 10 Bar

- Silcon seal (others available)

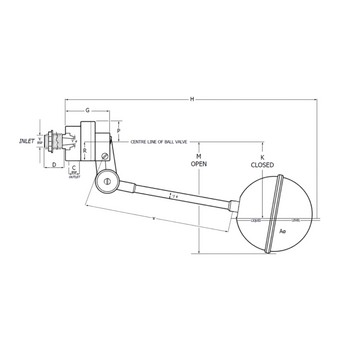

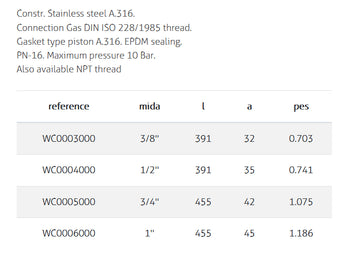

- Made from stainless steel

- Only two positions, fully open and fully closed

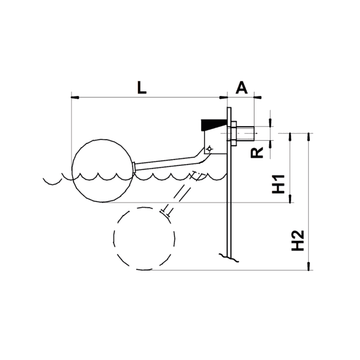

- Connection with Gas thread cylindrical DIN – ISO 228/1985

- Nominal pressure PN – 16, maximum variable pressure 10 bar

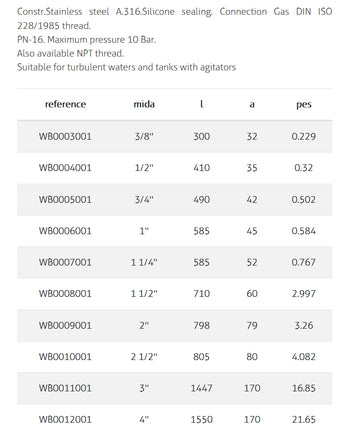

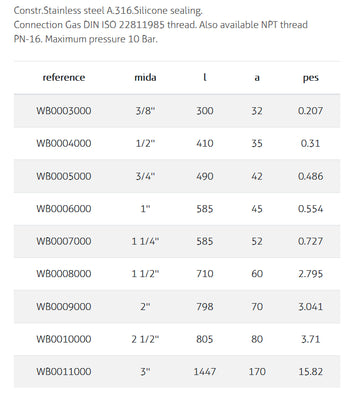

- Constr. Stainless steel A.316.Silicone sealing.

- Connection Gas DIN ISO 228/1985 thread. PN-16. Maximum pressure 10 Bar.

- Also available NPT thread. Functionality: to support a minimum in the tanks

- Valve system patented and guarantees a perfect seal with minimum force from the float.

- Connection with Gas Thread, cylindrical DIN-ISO 228/1985.

- Made from stainless steel 18/8 (AISI 316 / DIN 1.4401 & CF8M, DIN 1.4408).

- Nominal pressure PN-16. Maximum variable pressure 10 bar.

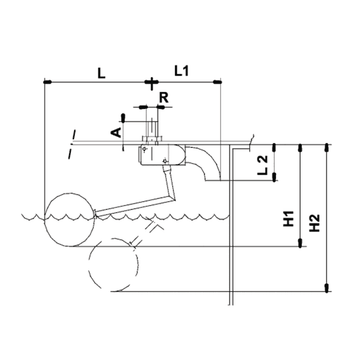

- Made from stainless steel 18/8/2 (AISI 316, DIN 1.4401 y CF8M, DIN 1.4408).

- Swing type valve with silicone shutter, available in VITON, EPDM, PTEF, etc., on demand.

- Valve system patented and guarantees a perfect seal with minimum force from the float.

- Connection with flange PN – 16/10, DIN 2576 (2527)

- Nominal pressure PN – 16, maximum variable pressure 10 bar

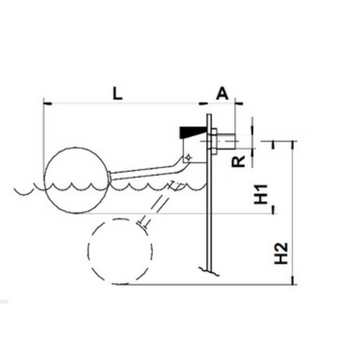

- Connection with Gas Thread, cylindrical DIN-ISO 228/1985.

- Made from stainless steel 18/8 (AISI 316 / DIN 1.4401 & CF8M, DIN 1.4408).

- Swing type valve with silicone shutter

- Available in VITON, EPDM, BUNA, PTEF

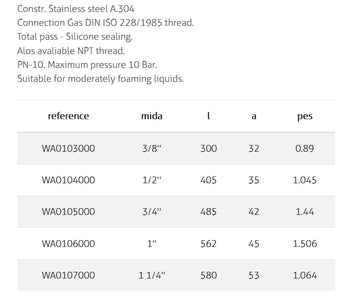

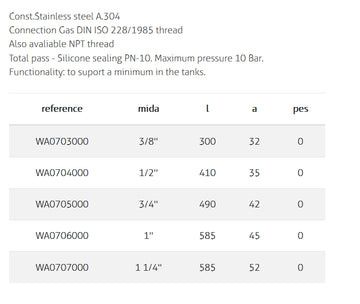

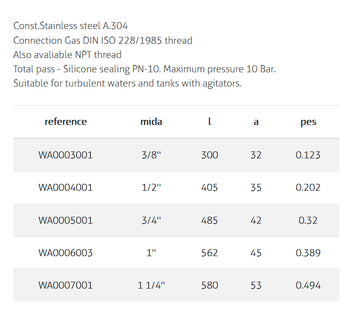

- Const.Stainless steel A.304

- Connection Gas DIN ISO 228/1985 thread

- Also avaliable NPT thread

- Total pass - Silicone sealing PN-10. Maximum pressure 10 Bar.

- Functionality: to suport a minimum in the tanks.

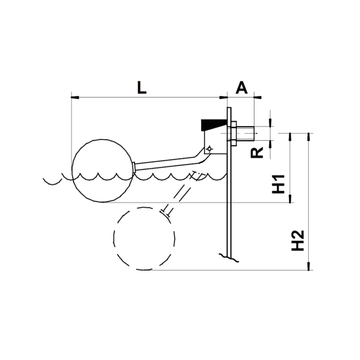

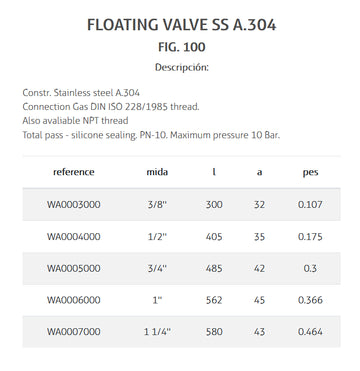

- Made from stainless steel

- Swing type valve with silicone shutter

- Available in Viton, EPDM, Buna, PTFE

- Connection with Gas thread cylindrical DIN – ISO 228/1985.

- Nominal pressure PN – 10, maximum variable pressure 10 bar

- Made from stainless steel

- Swing type valve with silicone shutter

- Available in Viton, EPDM, Buna, PTFE

- Connection with Gas thread cylindrical DIN – ISO 228/1985

- Nominal pressure PN – 10, maximum variable pressure 10 bar

- Made from stainless steel

- Swing type valve with silicone shutter

- Available in Viton, EPDM, Buna, PTFE

- Connection with Gas thread cylindrical DIN – ISO 228/1985.

- Nominal pressure PN – 10, maximum variable pressure 10 bar

- 10mm to 65mm port diameter

- 3/8” to 2 1/2” BSP connection

- All 316 stainless steel

- Flow rates up to 79,275 litres per hr

- Rated up to 10 Bar

- Silcon seal (others available)