FAFNIR

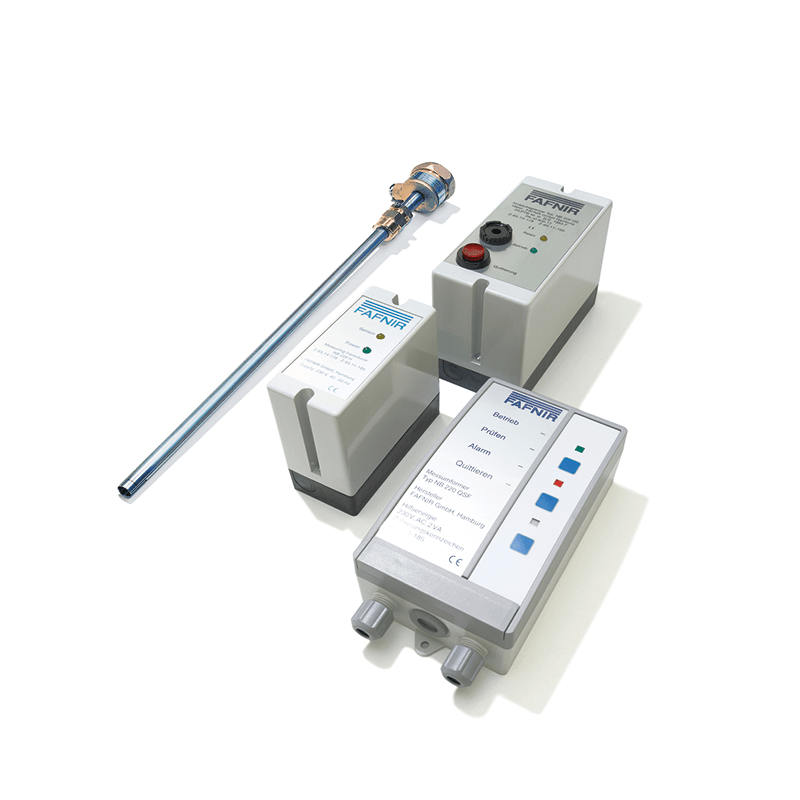

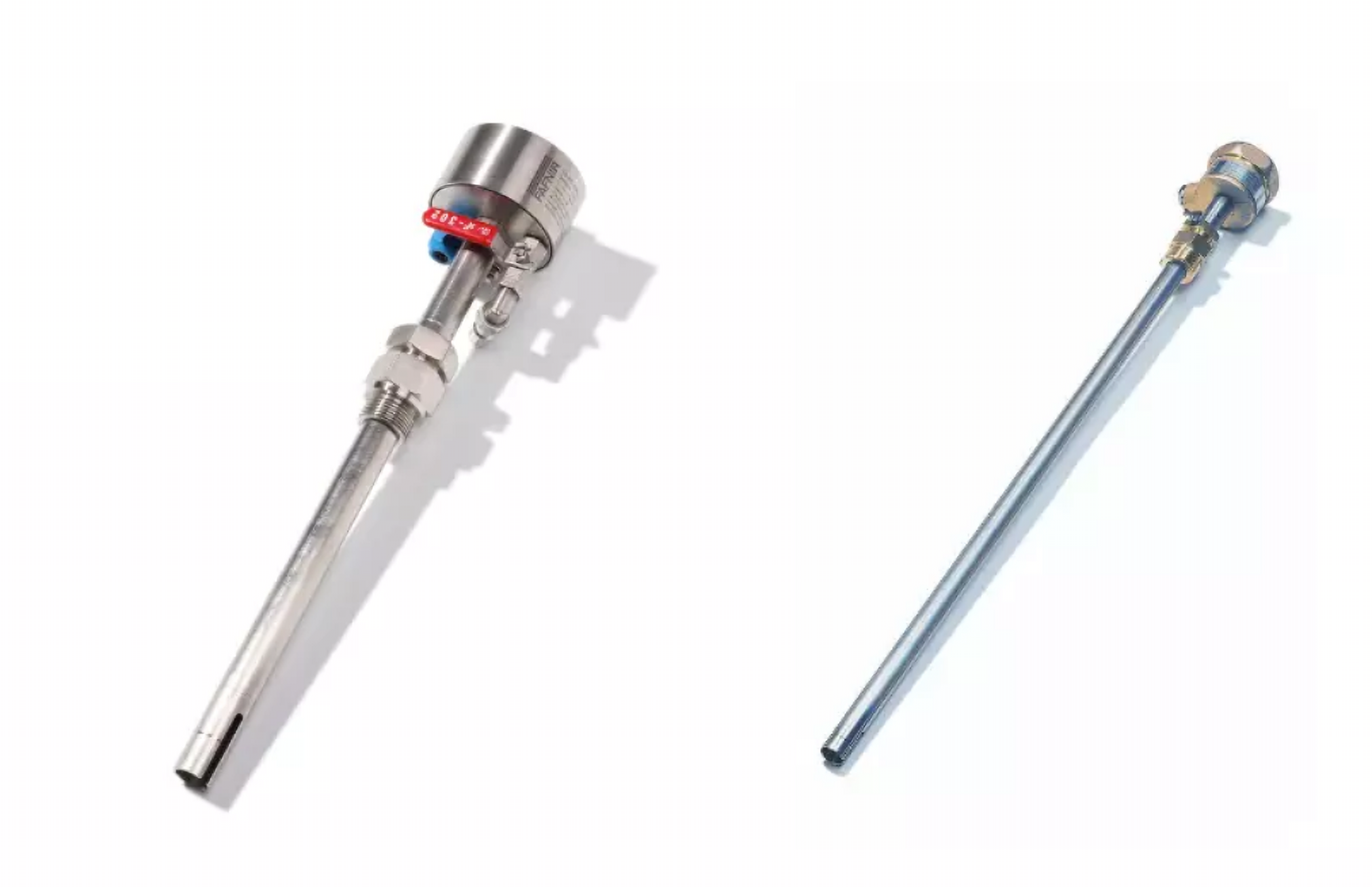

GWG Overfill Prevention Sensor

- Equipment Type: Overfill prevention

- Liquid: Diesel / Heating Oil, Petrol, LPG, LNG, Oil

- Vessel: Underground Storage Tank, Overground Storage Tank, Bulk Tank

- Certification: None

£0.00

In Stock

Sold out