HONSBERG

Honsberg in Remscheid has ensured high-quality products in measuring and monitoring technology since 1963.

Their devices measure and monitor flow, level, pressure and temperature. Consequently, they supply the market in various areas and applications, including wastewater treatment plants, diesel engines, hardening facilities, compressors and construction machines, machine tools, paper and print machines, and cooling systems.

Customers rely on the excellent quality of their products in all of these areas and applications. In addition, they develop customised solutions for customer-specific applications in their R&D department to suit various requirements.

Their measuring instruments are manufactured in their factory in Remscheid to the highest quality standards. As a result, their measuring instruments feature high-quality workmanship, the best materials, and consistently outstanding measurement accuracy, durability, and resistance.

It is precisely the harsh conditions our customers place on Honsberg products that their high-quality equipment must withstand. After all, this is why Honsberg develops, manufactures, and tests them themselves.

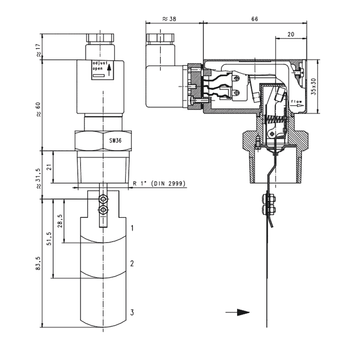

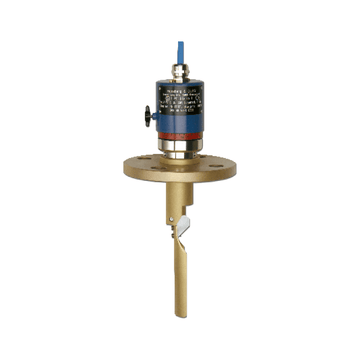

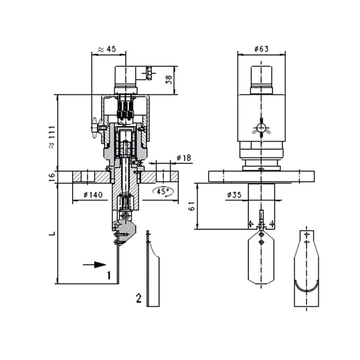

- 4 x paddles supplied with each switch

- Pipe sizes from 25mm to 200mm

- 1”BSP threaded pipe fitting

- Brass or stainless steel option

- 0.9 - 6.7 m3/h H2O switching range

- C/O Micro-switch Rated 250Vac/5A

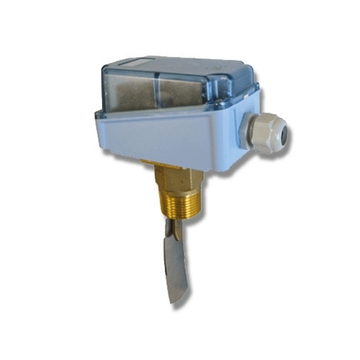

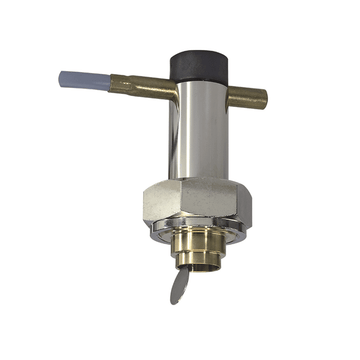

- 4 x paddle supplied with each switch

- Pipe sizes from 1” to 6” diameter.

- Standard 1” BSP fitting

- 0.19 to 39.90 m³/h switching ranges

- Brass or stainless steel body

- C/O Micro-switch Rated 250Vac/15A

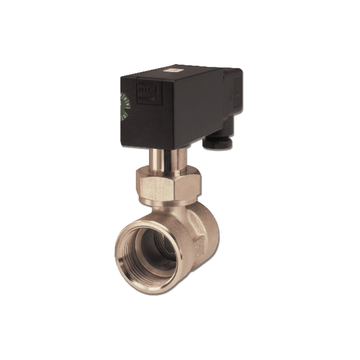

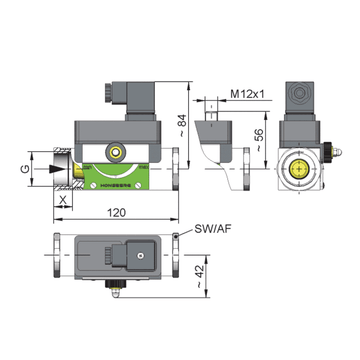

- Nominal pipe sizes 10-50 mm

- 3.5 - 69 l/min switching range

- 3/8” - 2” BSP threaded connections

- Low pressure loss

- Brass or stainless steel option

- C/O reed switch rated at 230Vac/1A

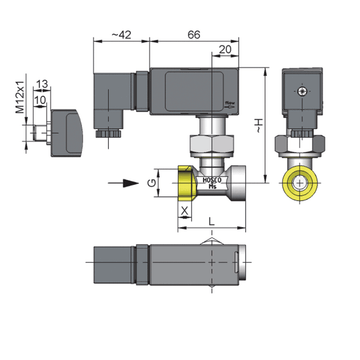

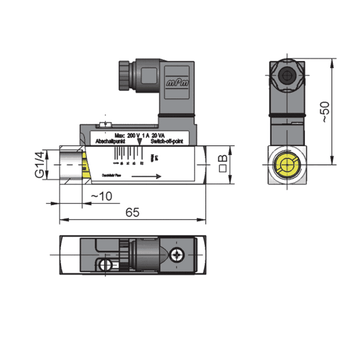

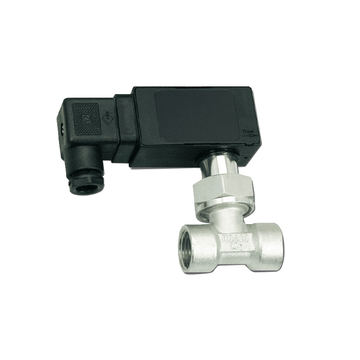

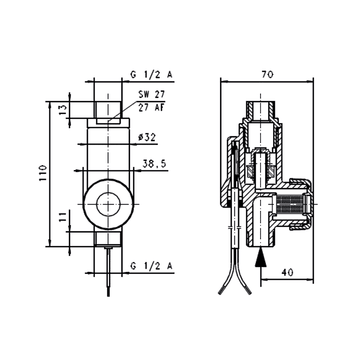

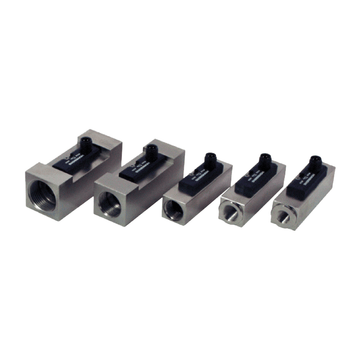

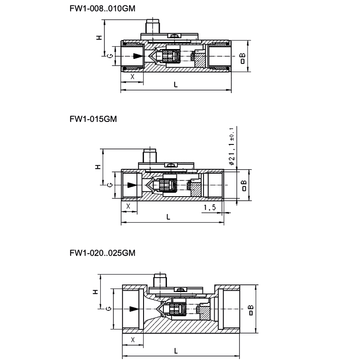

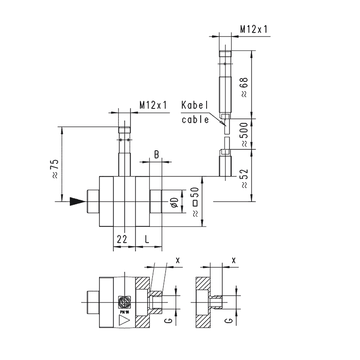

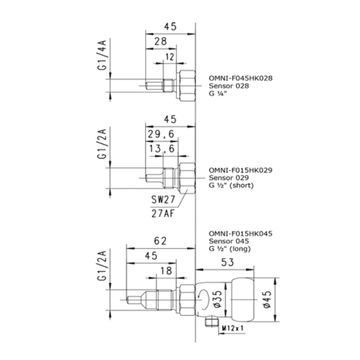

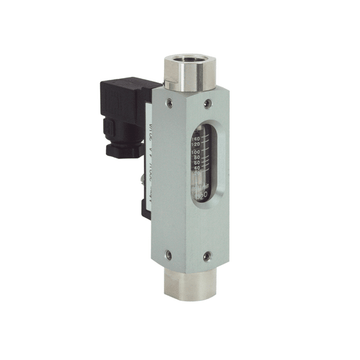

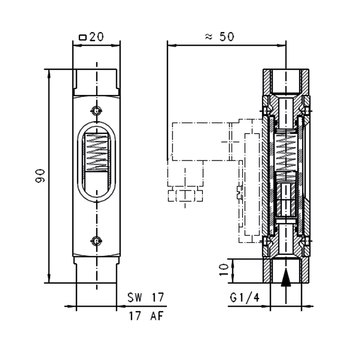

- 8mm pipe size

- 0.04 - 3 l/min switching range

- 1/4” threaded connections

- Pressure up to 350 bar

- Brass or stainless steel option

- -20..+100 °C optionally 160 °C

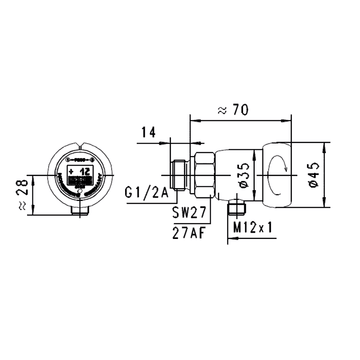

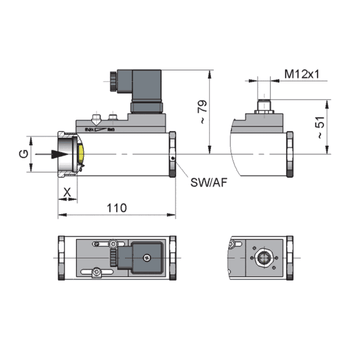

- Pressure Transducer System with Switch Points

- Up to 400 bar measurement range

- Over-pressures up to 600 bar

- Analog output, two switching outputs

- 1/2” BSP thread

- Back Lit LCD display

- Easily adjustable

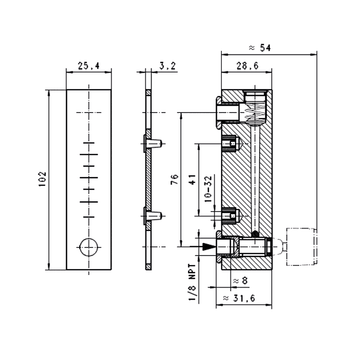

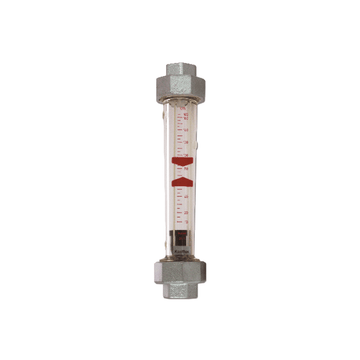

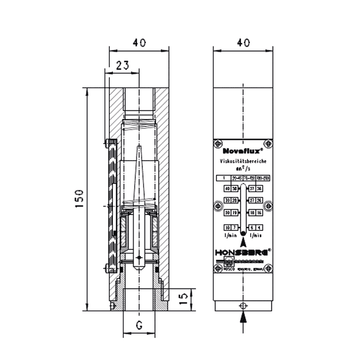

- Process connection: female thread 1/8 "NPT

- Metering range: 0.005..25 l/min

- Pressure resistance: PN 6 bar

- Media: water, gases

- Weight: 0.13 kg

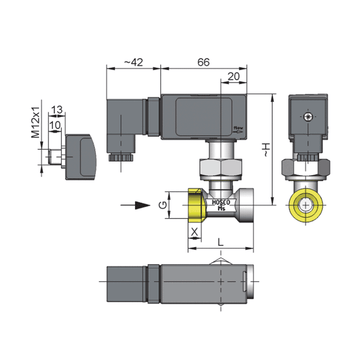

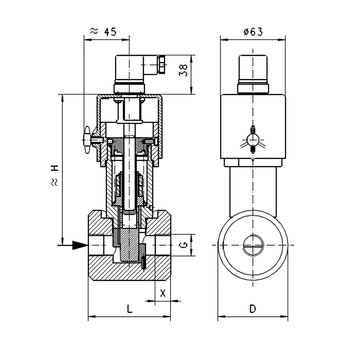

- Nominal pipe sizes 8-25 mm

- 0.1 - 80 l/min switching range

- 1/4” - 1” BSP threaded connections

- Pressure 200 bar (500 bar option)

- Brass or stainless steel option

- Viscosity compensated version(HD2K)

- Nominal pipe sizes 10-50 mm

- 4 - 93 l/min switching range 3/8” - 2” BSP threaded connections

- Low pressure loss

- Brass or stainless steel option

- C/O micro switch rated at 250Vac/5A

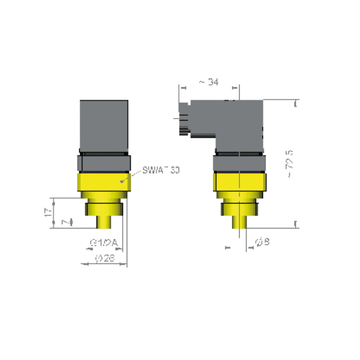

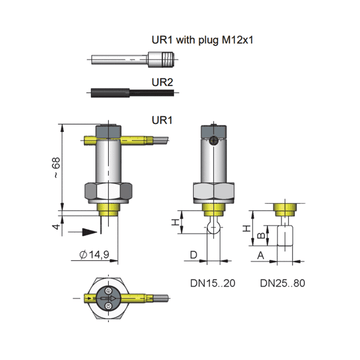

- Screw-in-thread

- Brass/Stainless Steel materials

- Highly reproducible

- Normally open or normally closed contact

- ATEX approved

- High temperature resistance

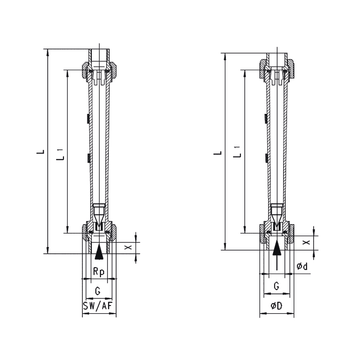

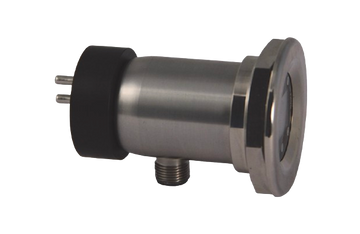

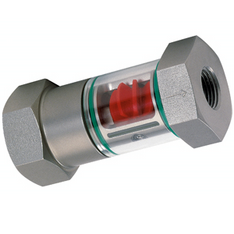

- Double-sided large-surface window

- Natural glass

- Display of flow rate

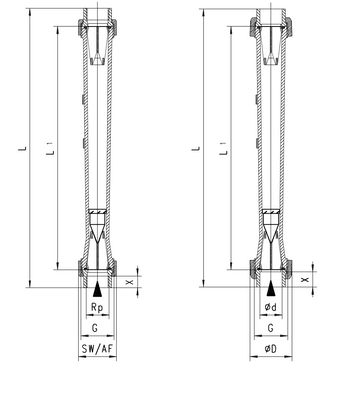

- Nominal width: DN 8.0.25

- Process connection: female thread G 1/4..G 1

- Display range: 0.7..60 l/min

- Pressure loss: up to 0.7 bar

- Pressure resistance: up to 0.7 bar

- Pressure resistance: PN 16 bar

- Metal insert up to 30 l/min.

- Media temperature up to 300°C

- Nominal widths DN 15 and DN 20

- Brass/stainless steel materials

- Optional installation

- No wear-parts

- No additional power supply

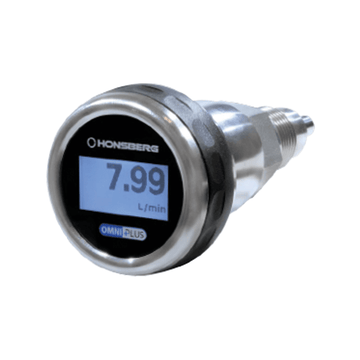

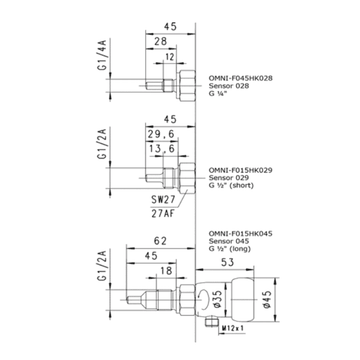

- Momentary value indicator and totalisation

- Pulse output with adjustable pulse per volume

- Antivalent outputs

- Analogue output of the momentary value

- Simple guided menu via graphics display

- 40°C-120°C Set Points (10° increments)

- Max temperature 140°C

- Switch rating up to 250V

- 1/2” or 3/4” BSP thread

- Brass or stainless construction

- Rated to 100 bar

- Suitable for both liquids & gases

- 3/8″ to 2″ BSP sizes

- Optional high & low switch points Optional 4 – 20mA transmitter

- Pressures up to 16 bar

- PVC or cast iron connections

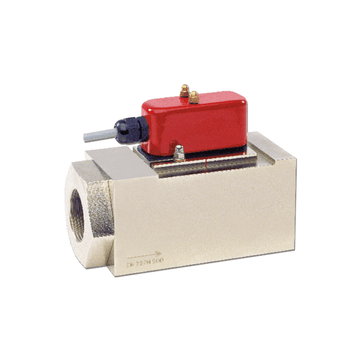

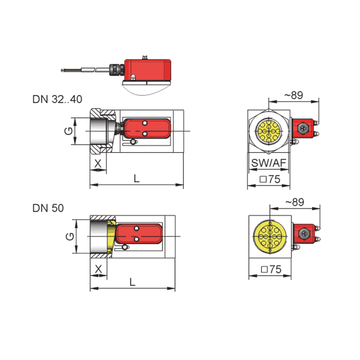

- For 32-50 mm pipe size

- 2-220 l/min switching range

- 1 1/4” - 2” threaded connections

- Brass or stainless steel option

- Pressure up to 200 bar

- Viscosity stabilised

- For 15 mm nominal width

- 0.4-12 l/min switching range

- 1/2” male threads

- Integrated filter

- Plastic wetted parts

- Up to 10 bar pressure

- For 15 mm pipe size

- 1 l/min switching point

- 1/2” threaded connections

- Bi-directional flow switching

- Pressure up to 300 bar

- Viscosity stabilised

- Nominal pipe sizes 8-25 mm

- 0.1 - 80 l/min switching range

- 1/4” - 1” BSP threaded connections

- Optionally side or top displays

- Brass or stainless steel option

- Viscosity compensated version(HD2F)

- Nominal pipe sizes 8-25 mm

- 1 - 11 l/min switching range

- 1/4” - 1” BSP threaded connections

- Not affected by dirt

- Brass connection material

- 230Vac/0.5A reed switch

- Nominal pipe sizes 8-25 mm

- 0.4 - 60 l/min switching range

- 1/4” - 1” BSP threaded connections

- Pressure 200 bar (500 bar option)

- Brass or stainless steel option

- -20..+120 °C (-20..+150 °C option)

- 40 to 200mm nominal width

- 40 to 1050 l/min switching range

- -20-+90 °C (-20-+200 °C option VMX)

- Flange process connection DIN 2527

- Precise stepless adjustment

- ATEX option available

- Nominal pipe sizes up to 80mm

- 5-174 l/min switching range

- Brass / Stainless Steel / Plastic Welded

- 1/2″ BSP connection

- Low Pressure Loss

- ATEX option

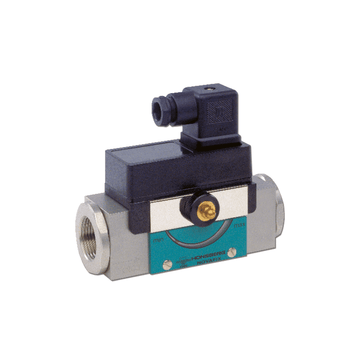

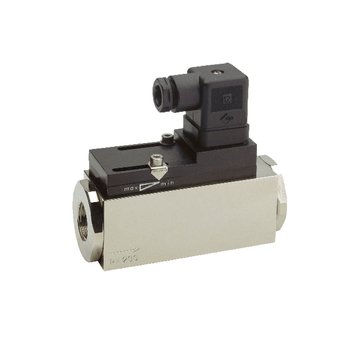

- Differential pressure measurement for non-aggressive gases

- Short reaction time

- Analog output, two switching outputs

- Clear, easily legible, illuminated LCD display

- Designed for industrial use

- Small, compact construction

- Very simple installation

- Control panel assembly (IP65)

- Parameterisation of LABO/FLEX/OMNI

- For Windows PC with USB

- Connection in device supply line

- Bypass mode for output signals

- Measuring ranges from 0..200°C

- Analog output 4..20 mA or 0..10 V

- 2 limit value switches

- Probe stainless steel 1.457

- Ranges covering 0.7..100 l/min H2O

- Ranges covering18 to 700 l/min air (1 bar)

- 16 bar max

- Brass connections

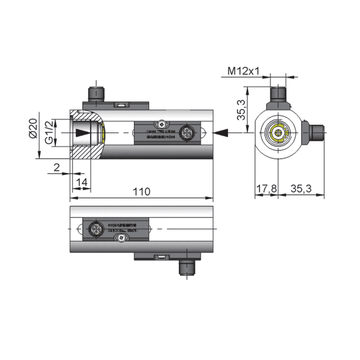

- High precision and linearity

- For oils and other viscous media

- Ranges from 0.02 to 150 l/min

- Light and compact construction in an aluminium housing

- For cost-sensitive applications

- High precision and linearity

- For oils and other viscous media

- Ranges from 1.5 to 2500 l/min

- Connection G 1..G 21 /2

- Very low dependence on viscosity

- Can be used up to 40,000 mm²/s (cSt)

- Linear frequency output (push-pull)

- Light and compact device (aluminium housing)

- Operation and measurement possible with forwards and reverse flow

- For cost-sensitive applications

- All plastic (POM or PVDF) flow indicator

- Can be installed in any position

- Low ‘start-up’ benefit due to low friction design

- 3/8″ and 1″ BSP sizes

- Maximum pressure 16 bar

- Maximum temperature 60ºC

- Rotor on both sides directly behind natural glass

- Installation location as desired

- Mechanical flow indicator

- With twin rotor for quantitative flow display

- Medium temperature 100°C

- High temperature resistance

- Double-sided large-surface window

- Natural glass

- Display of flow rate

- High temperature resistance

- Double-sided large-surface window

- Natural glass

- Visualisation of the flow rate

- No moving parts internally

- Internal wiper provides ability to clean the glass without removing the device.

- Installation location as desired

- For heavily soiled or coloured fluids

- 360 ° visibility

- Easy to fit to existing pipework

- Sizes from 1/4″ to 2″ BSP

- Large glass area allow viewing from any direction

- Maximum pressure 6 bar

- Maximum temperature 70°C

- Brass body

- Metal inserts up to 210 l/min.

- Media temperature up to 200°C

- Nominal widths DN 32 to DN 80

- Brass/stainless steel materials

- Male thread Installation location as desired

- No need for auxiliary power

- Can be used on site for: parameter modification, firmware update, adjustment of inputs and outputs

- Can be connected via USB

- Simple filling counter with programmable end signal

- Control switchover at present value

- Automatic, dynamic change of display unit and decimal places in the graphics display

- Simple guided menu via graphics display

- Flow transmitter with display

- For pipe diameters of DN 32 or larger

- Stainless steel version

- Suitable for retrofitting in existing pipelines with tapping clamps

- Analog output 4..20 mA or 0..10 V

- Two programmable switches

- Selectable units in the display

- Parameter change with rotating ring

- Electronics housing with non-scratch, chemically resistant glass

- Rotatable electronic housing for best reading position

- Flow transmitter with display

- For pipe diameters of DN32 or larger

- Plastic version

- Suitable for retrofitting in existing pipelines with tapping clamps

- Analog output 4..20 mA or 0..10 V

- Two programmable switches

- Selectable units in the display

- Parameter change via rotating ring

- Electronics housing with non-scratch, chemically resistant glass

- Rotatable electronic housing for best reading position

- Simple and affordable flow transmitter for pipe diameters of DN32 or larger

- Stainless steel version

- Suitable for retrofitting in existing pipelines with tapping clamps or weld-on nozzles

- Simple and affordable flow transmitter for pipe diameters of DN32 or larger

- Plastic version

- Suitable for retrofitting in existing pipelines with tapping clamps or weld-on nozzles

- Flow transmitter for water and other liquids with integrated temperature measurement

- Fast response timeIntegrated volume meter with preset

- Measuring method without moving parts, no wear

- Stainless steel material coming into contact with medium

- 1 analog output (20 mA / 10 V)

- 2 versatile configurable switching outputsIO-Link interface

- High-resolution graphic LCD Parameters programmable with multifunction ring

- Waterproof all-metal housing (IP67)

- Mineral glass front, scratch-proof and chemically resistant

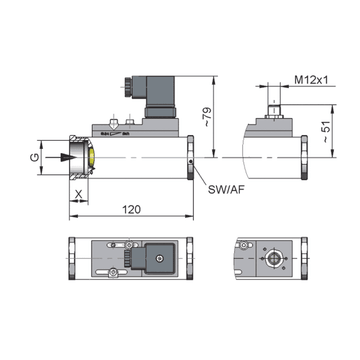

- From 0.4 to 100 l/min flow ranges

- Very fast response time

- High Overload Protection

- High Max Flow

- Low pressure Loss

- Compact Design

- 150c High Temperature Option

- 100 bar High pressure Version Available

- 1/4” or 1/2” Screw in connection

- 2 - 150 cm/s metering range

- 4-20 mA or 0-10V output

- PNP / NPN switch output

- All stainless wetted parts

- Fast response times

- For 8 mm pipe

- 0.005 - 5l/min display ranges

- 1/4” BSP threaded connections

- Maximum temperature 100 °C

- Switching contact option(VFR)

- Brass or Stainless Steel

- Nominal pipe sizes 8mm to 25 mm

- 2 - 80 l/min switching ranges

- 1/4” -1” BSP threaded connections

- Maximum temperature 100 °C

- Viscosity stabilised option (NJV)

- Brass or Stainless Steel

- Nominal pipe sizes 8mm to 80 mm

- 1 - 600 l/min switching ranges

- 1/4” -3” BSP threaded connections

- Medium Temperature -20 °C to 120 °C

- 720 l/min max flow

- ATEX option available